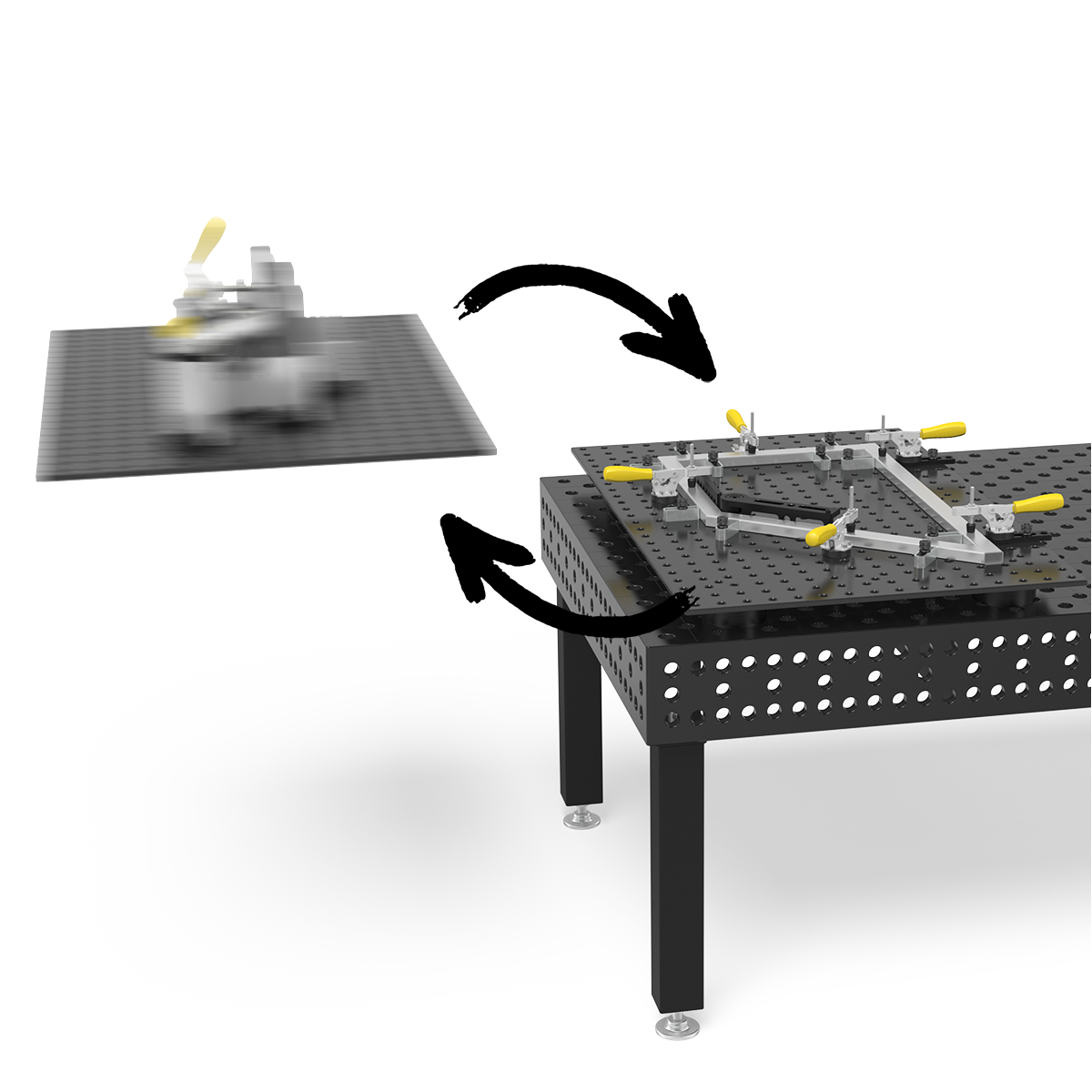

Modify your reused fixtures in a few easy steps with the Siegmund zero point clamping system.

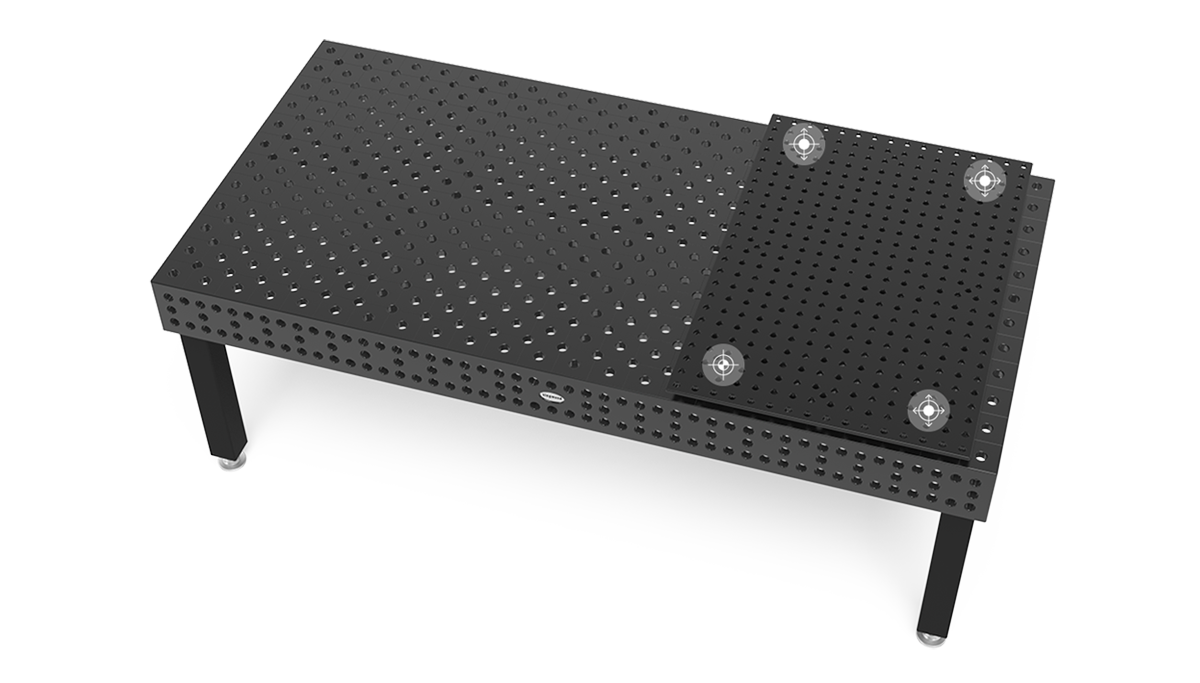

Simply remove and replace the complete perforated plate and fixture assembly and replace with another.

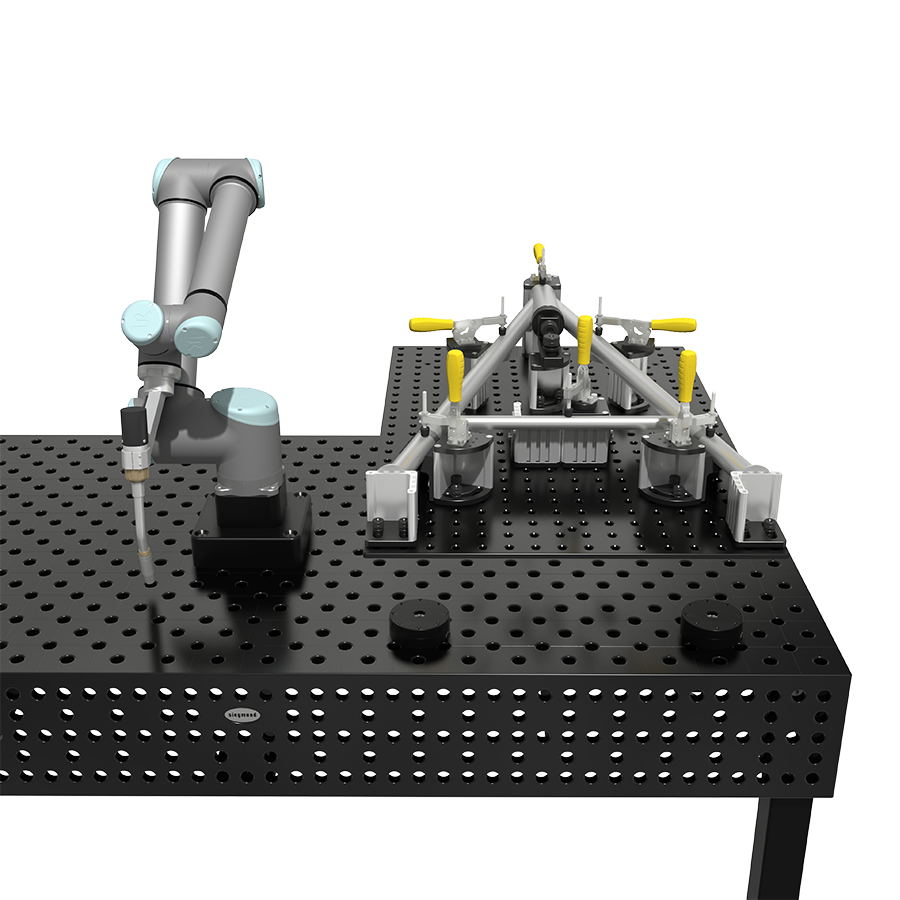

Automate your workplace now with Siegmund's zero point clamping system and upgrade your welding table to increase the robot working load and ensure consistent quality.

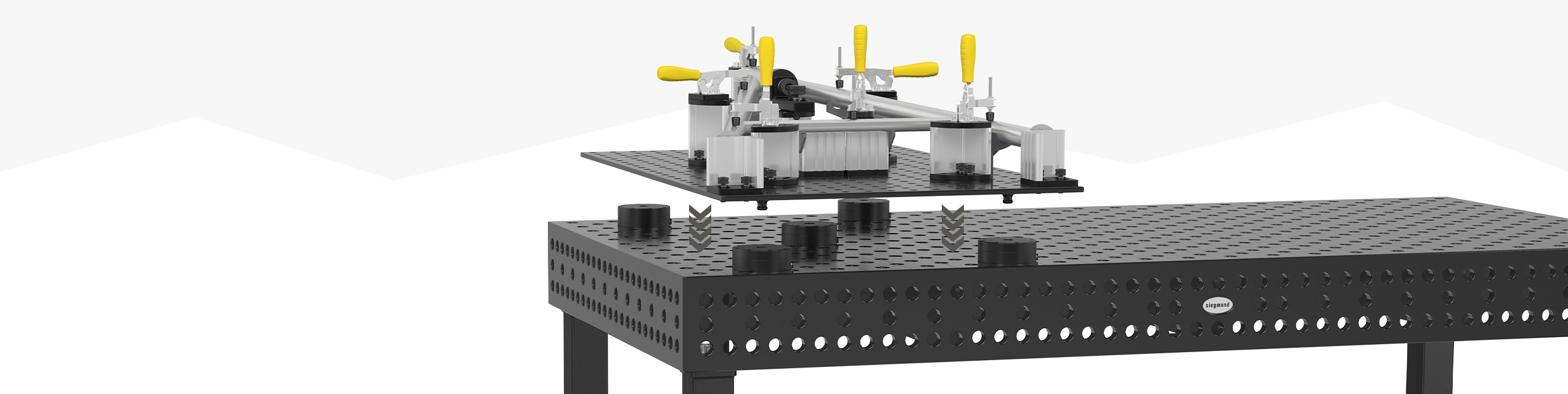

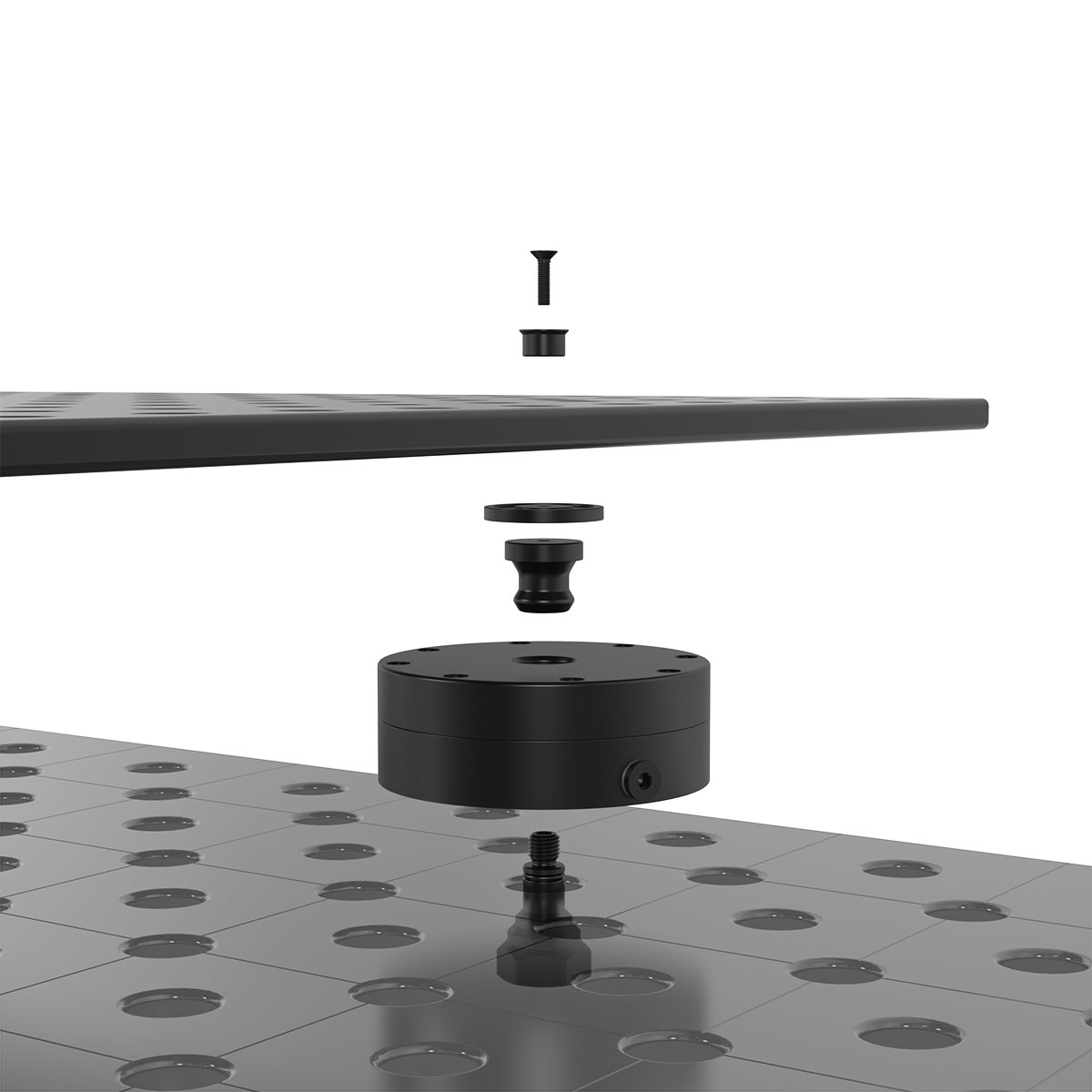

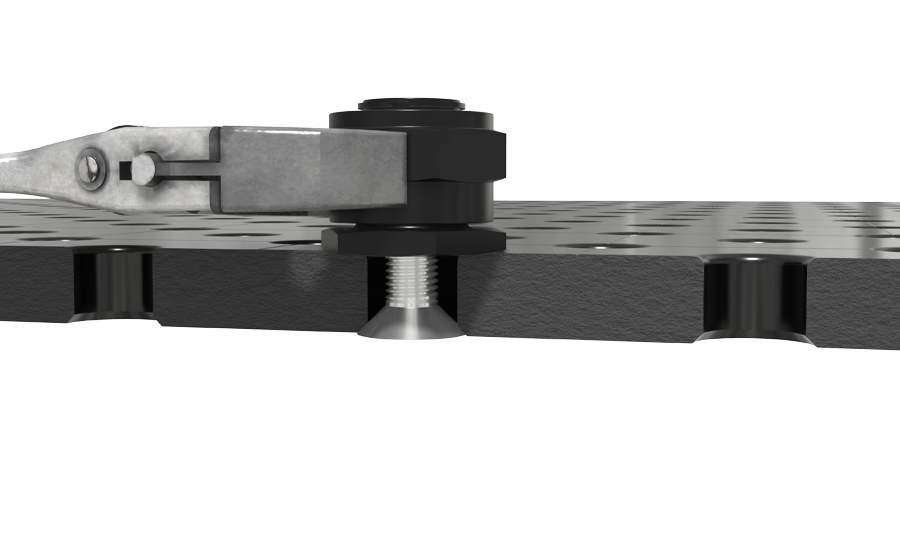

The modules of the zero point clamping system are centered and fastened in the borehole of the welding table. The perforated plate is fastened using clamping bolts via the zero point clamping system.

The perforated plate can be aligned on the welding table with the zero point clamping system. The centering is done via the sockets.

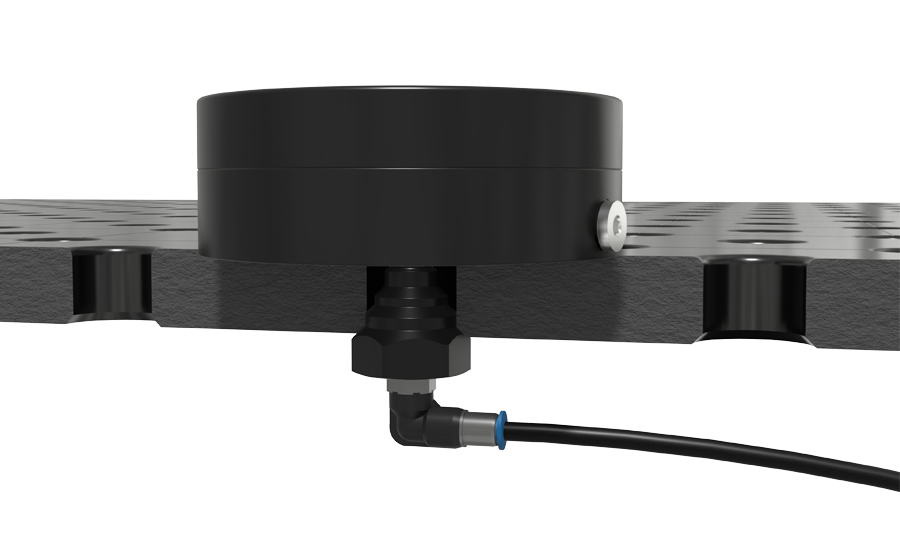

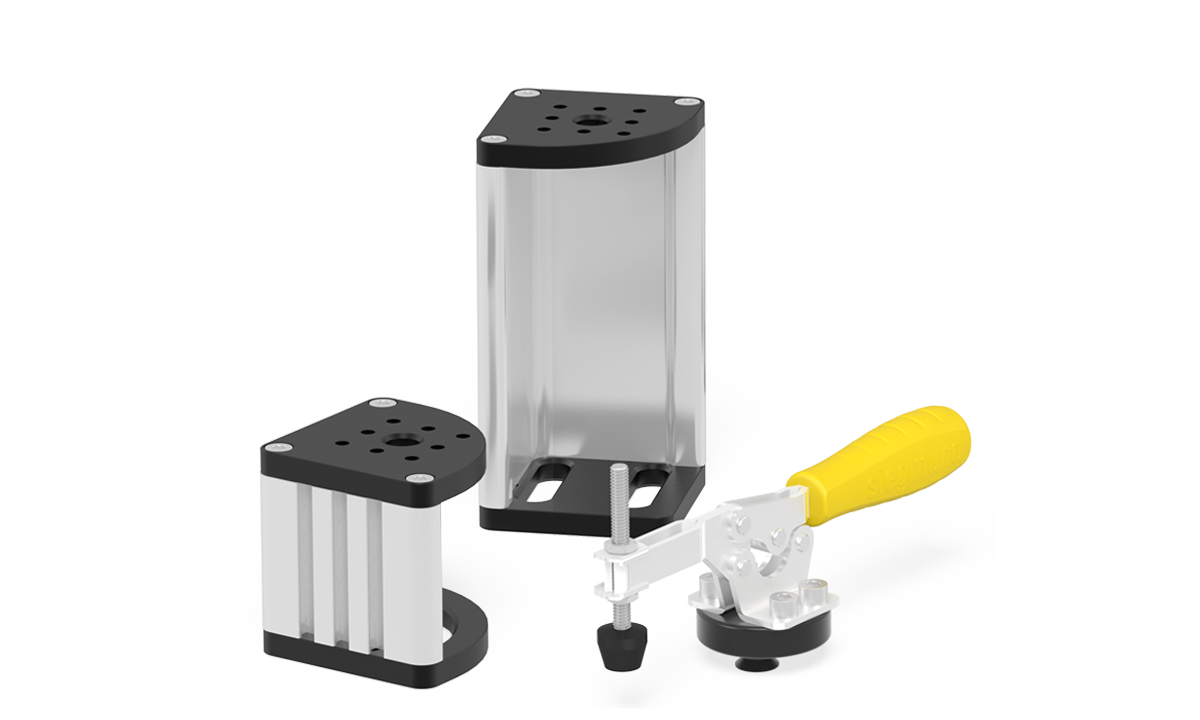

The zero point clamping system is available in two versions. The mechanical variant is clamped or opened using an open-jaw wrench. With the pneumatic variant, the clamping bolt is loosened using compressed air. Without the supply of compressed air, the bolt is clamped.

In combination with the new clamping system, recurring welding devices can be manufactured with high accuracy and low down times. If a robot program already exists, you benefit from a minimal set-up time of your device.

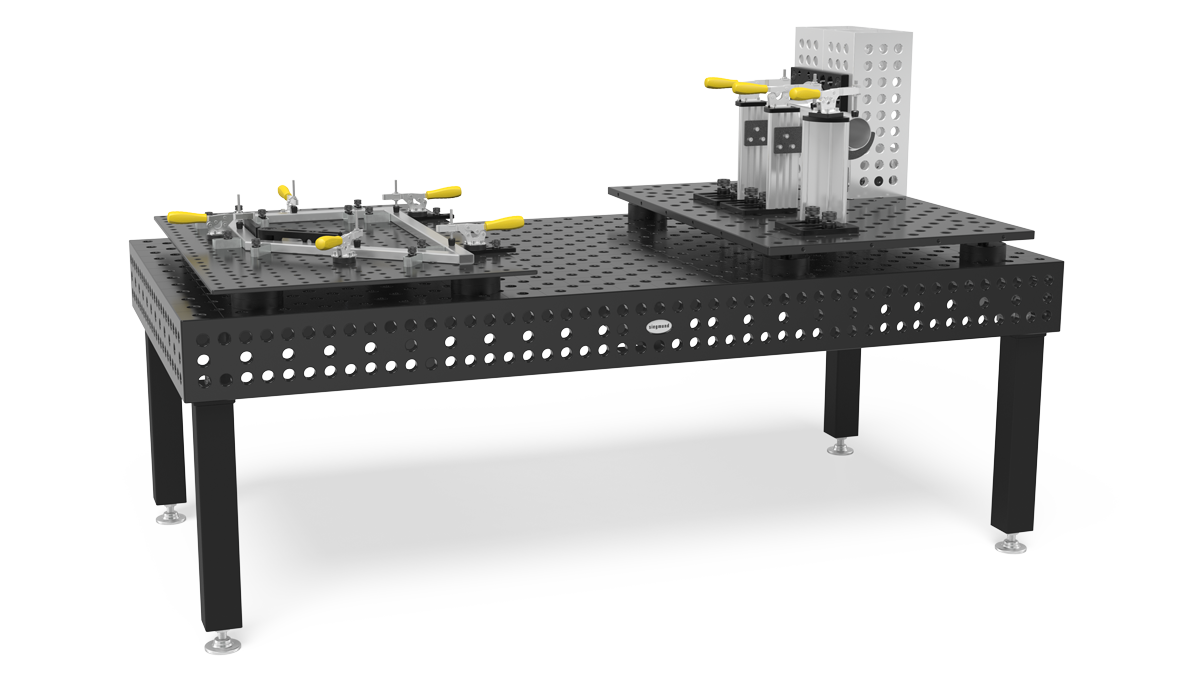

The ideal basis for your fixtures.

We offer plasma nitrided perforated plates with different system boreholes with 16 mm, 22 mm and 28 mm diameter and in diverse materials.

The surface boreholes enable easy fastening of components with the Siegmund tooling.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.