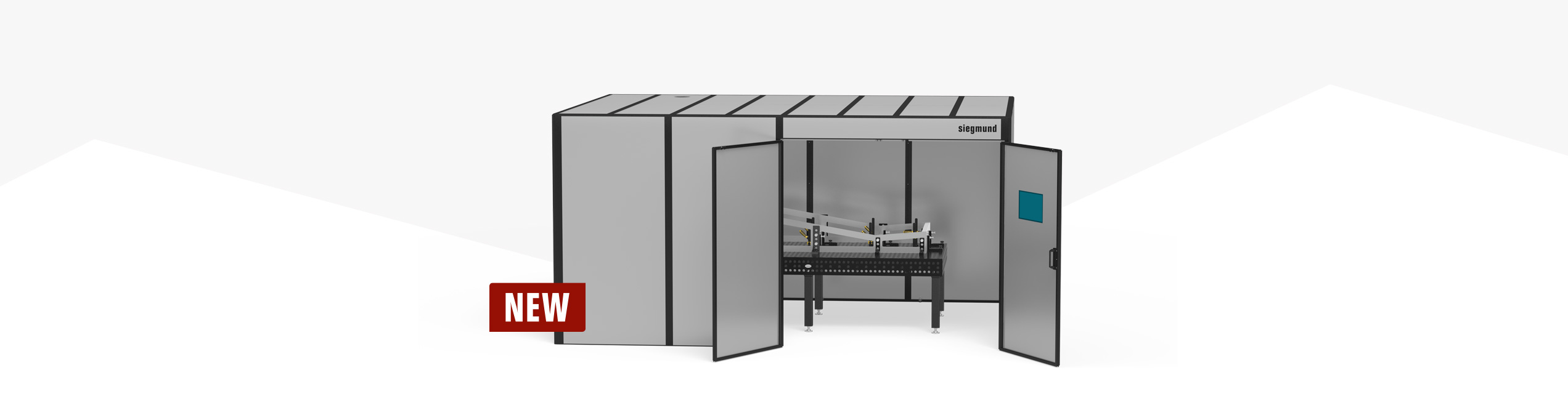

The Siegmund laser welding cell provides optimal protection against scattered radiation and reflections that can occur when working with lasers. With its innovative design and pre-assembled side walls, it is quickly ready for use. It is suitable for manual laser welding and laser cleaning in the wavelength range from 940 to 1090 nm.

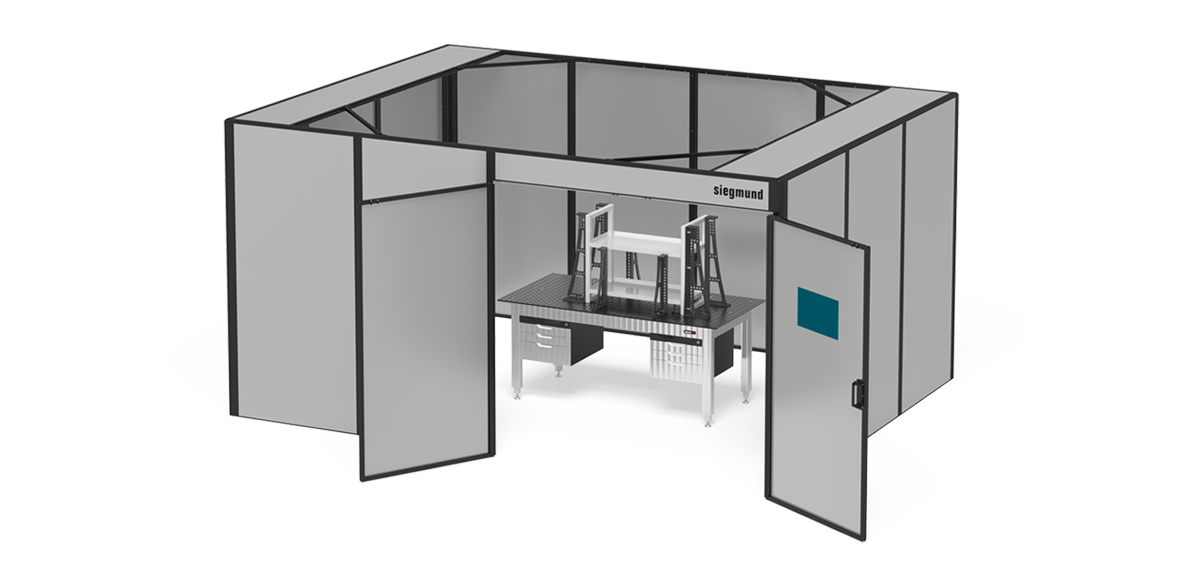

The Siegmund laser welding cell stands out with its wide range of configuration options and can also be expanded later with wall elements. Create your customized cell tailored to your specific requirements.

Manual laser welding has quickly established itself as an indispensable process in welding technology. In order to meet the increased safety requirements, Siegmund introduced a laser welding cell as a protective enclosure in 2023. With the launch of a completely new, innovative and modular generation of laser welding cells, we are setting new standards in terms of safety and flexibility.

Safety is our top priority, which is why we have had our laser welding cell comprehensively certified. It not only meets the highest safety standards but is also CE-compliant (safety component) and certified according to DIN EN 60825-4.

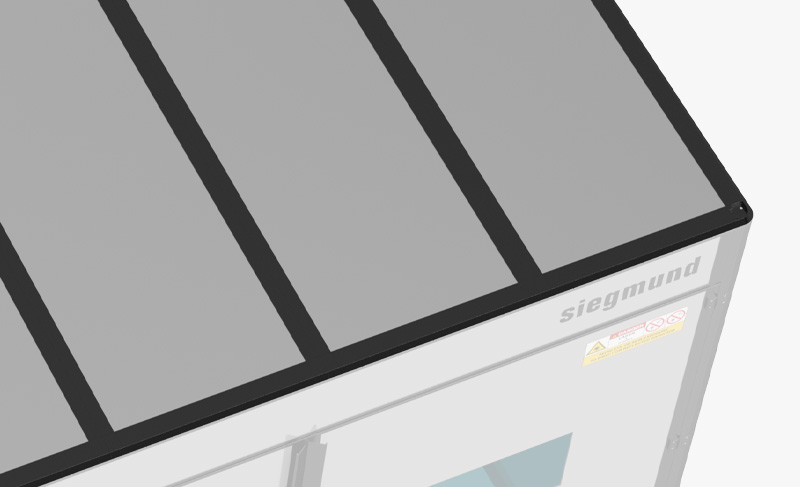

The side walls are made of special aluminum composite panels and aluminum profiles that are approved for working with lasers in the wavelength range from 940 to 1090 nm and are certified according to DIN EN 60825-4. They are delivered pre-assembled and only need to be screwed together.

The integrated protective viewing screen ensures a safe and clear view into the cell during the welding process and is certified according to DIN EN 60825-4 and DIN EN 207.

The closed certified roof with the option of connecting a welding fume extraction system offers additional protection.

Upon request, we offer a safety package for monitoring the cell. Installation is carried out by the customer.

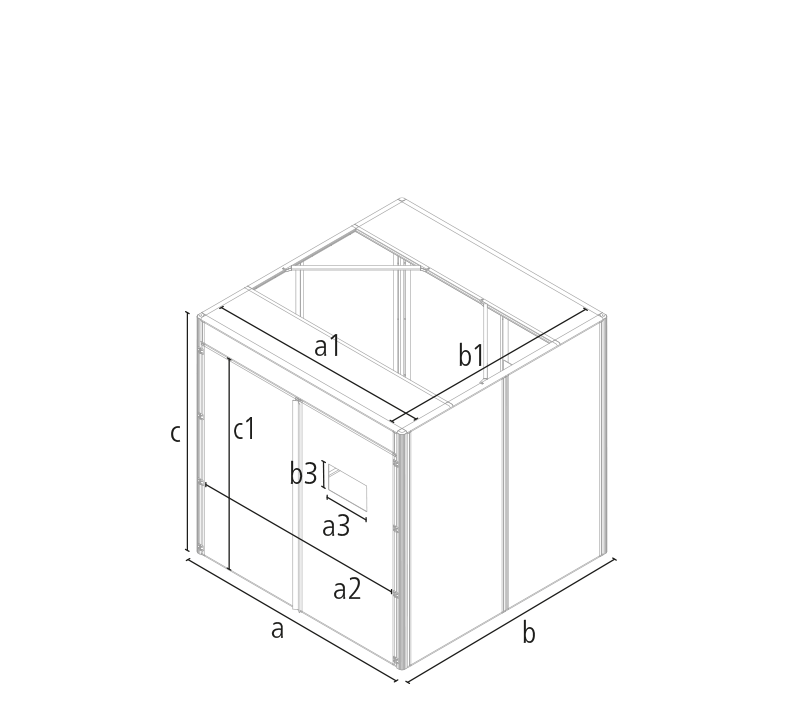

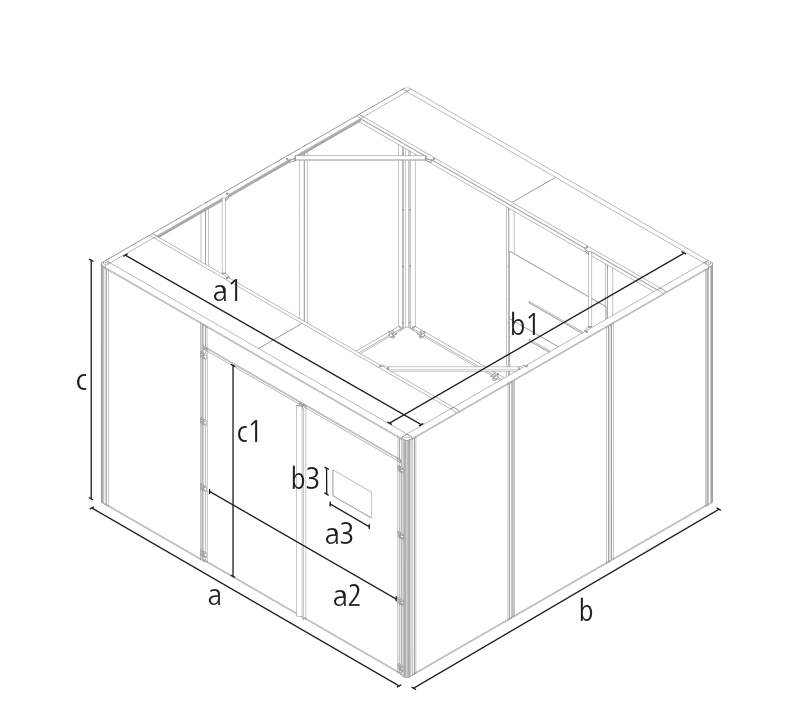

a = 2540 mm

b = 2570 mm

a1 = 2480 mm

b1 = 2480 mm

c = 2520 mm

c1 = 2240 mm

a2 = 2370 mm

a3 = 470 mm

b3 = 275 mm

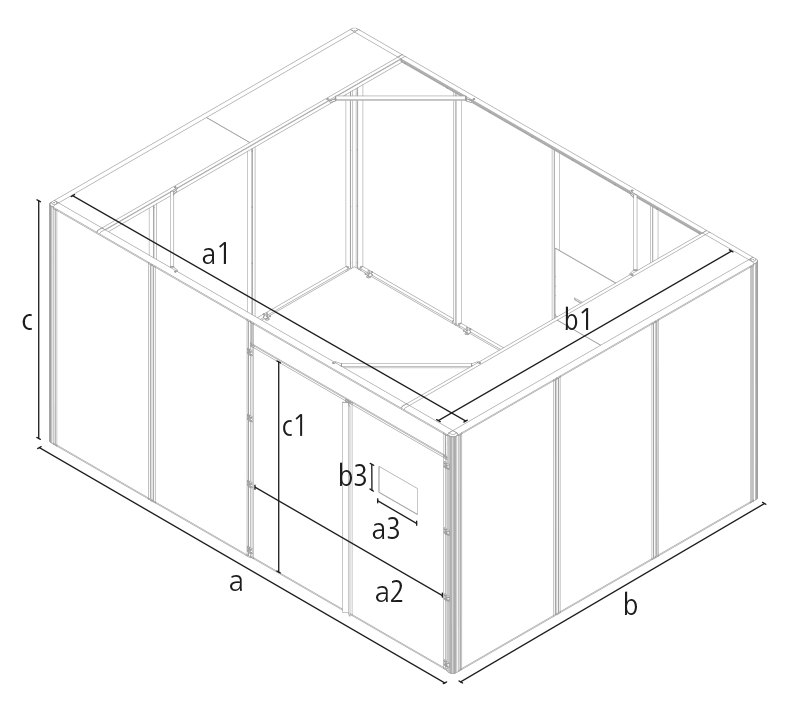

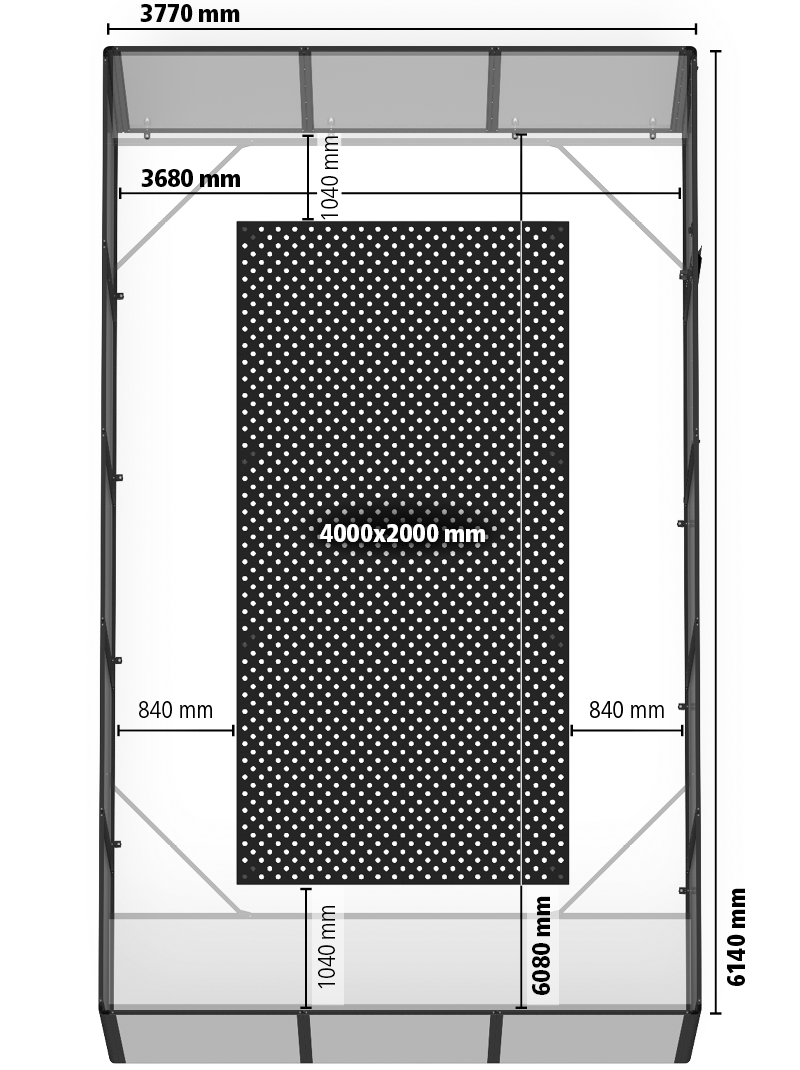

a = 3740 mm

b = 3770 mm

a1 = 3680 mm

b1 = 3680 mm

c = 2520 mm

c1 = 2240 mm

a2 = 2370 mm

a3 = 470 mm

b3 = 275 mm

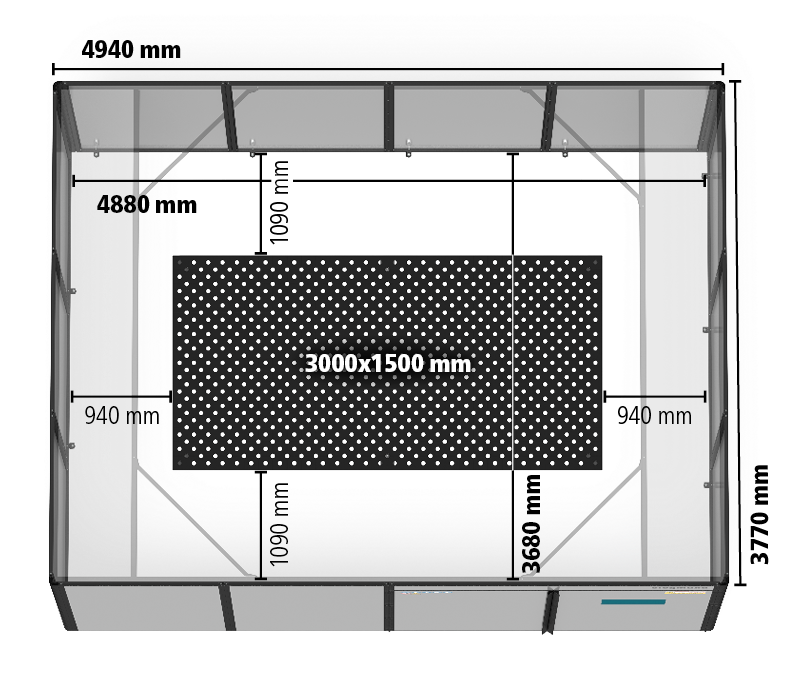

a = 4940 mm

b = 3770 mm

a1 = 4880 mm

b1 = 3680 mm

c = 2520 mm

c1 = 2240 mm

a2 = 2370 mm

a3 = 470 mm

b3 = 275 mm

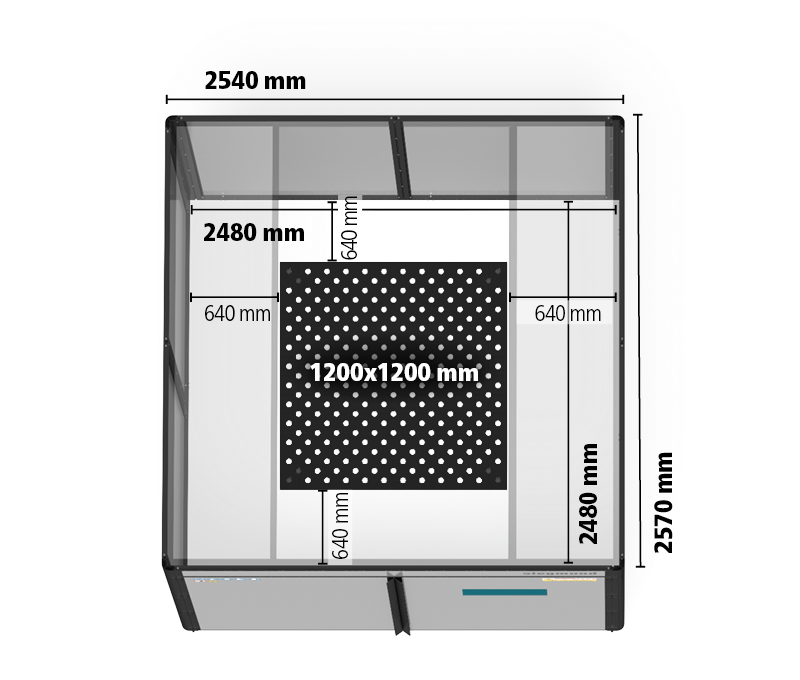

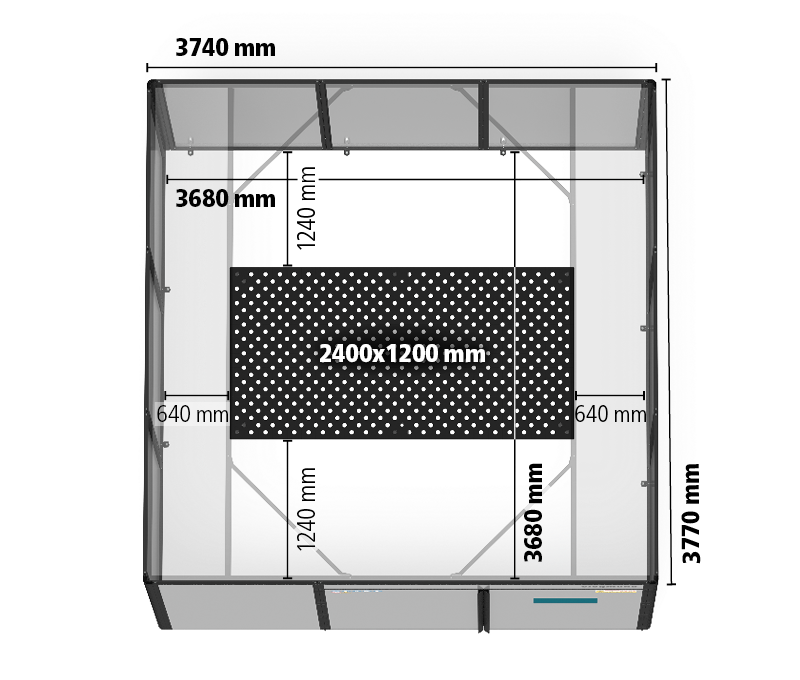

The work surface should be positioned at least 600 mm from the cell wall for a power output of 1,5 kW and at least 700 mm for a power output of 3 kW.

Laser welding cell 2480x2480 mm: recommended for welding tables up to 1200x1200 mm Laser welding cell 3680x3680 mm: recommended for welding tables up to 2400x1200 mm Laser welding cell 4880x3680 mm: recommended for welding tables up to 3000x1500 mm

Welding Table 1200x1200 mm

Welding Table 2400x1200 mm

Welding Table 3000x1500 mm

Combine a standard size laser welding cell with additional extensions to create your individual cell size.

Laser welding cell 3680x3680 mm 2x Extension wall element Welding Table 4000x2000 mm

Comment: Other products, such as a safety package, larger laser protection windows, lighting, or cells in U-shape or L-shape, are available upon request.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.