We offer a selection of welding tables made from various materials: from steel to tool steel, with and without plasma nitriding, to stainless steel. For particularly high demands, we provide our tool steels X8.7 and X8.8, which are exclusively available from us.

These tool steels are characterized by an exceptionally high base hardness, which is crucial for the high impact resistance and long lifespan of a welding table.

Additionally, our surfaces are refined through plasma nitriding and a BAR coating. This innovative treatment increases surface hardness and provides effective protection against scratches, corrosion, and the adhesion of weld spatter. The unique combination of high base hardness and surface finishing results in an exceptionally wear-resistant and durable surface that performs even under the most demanding conditions.

With our material selection and processing, we set new standards in quality and longevity.

|

|

Steel S355J2+N |

Steel S355J2+N + |

Tool Steel X8.7 + |

Tool Steel X8.8 + |

|

Basic hardness

|

★★

|

★★

|

★★★★★★

|

★★★★★★★★

|

|

Surface hardness

|

★★

|

★★★★★★

|

★★★★★★★★

|

★★★★★★★★★★

|

|

Impact-proof |

★★ |

★★★ |

★★★★★★★

|

★★★★★★★★★★

|

|

Scratch-proof |

★★ |

★★★★ |

★★★★★★

|

★★★★★★★★

|

|

Protection against weld spatter |

★ |

★★★★★★ |

★★★★★★★

|

★★★★★★★

|

|

Corrosion resistance

|

★

|

★★★★★★

|

★★★★★★

|

★★★★★★

|

|

Point load |

★★★ |

★★★★ |

★★★★★★

|

★★★★★★★

|

|

Flatness in its new state |

★★★★★★★ |

★★★★★★★ |

★★★★★★★

|

★★★★★★★

|

|

Maintenance of the flatness under heavy use |

★ |

★★★ |

★★★★★

|

★★★★★★★

|

|

Life span |

★★ |

★★★★★ |

★★★★★★

|

★★★★★★★

|

Die Schweißtische von Siegmund werden bereits seit 2009 serienmäßig plasmanitriert. Als Vorreiter in diesem Bereich haben wir durch die jahrelange Erfahrung und kontinuierliche Optimierung des Prozesses, einen Schweißtisch für die härtesten Anforderungen geschaffen, der in Sachen Robustheit und Langlebigkeit kaum mit anderen Produkten zu vergleichen ist.

Plasma nitriding is a thermochemical diffusion process for surface layer hardening. The surface layer of a workpiece or component is enriched with nitrogen, which forms a wear and corrosion protection layer on the component surface and in the area close to the surface. The manufacturing process takes place under vacuum at around 500 degrees Celsius. In conjunction with additional production steps, we achieve a nearly distortion-free product.

Plasma nitriding is one of the most environmentally friendly hardening processes because only nitrogen, hydrogen and oxygen are required for the hardening process. These gases are the main components of the air. At Siegmund, the required energy is provided exclusively electrically, instead of the fossil fuels that are otherwise customary on the market for heating the components.

The hardened surface makes the welding tables highly resistant to scratches, dents, and wear, which extends their service life. In addition, the flatness is maintained even with intensive use and the resilience is increased by up to 30%.

The hardening process takes place at moderate temperatures, preserving the dimensional accuracy of the table. After nitriding, the tables are re-measured to ensure a nearly distortion-free result in combination with other production steps.

A dense protective layer gives the welding table a high resistance to moisture, welding residues and aggressive environments, ensuring its durability and longevity even under demanding conditions.

Plasma nitriding significantly reduces the adhesion of weld spatter to the surface. This makes cleaning easier and reduces maintenance, as weld residues can be removed effortlessly.

Unlike powder coatings or chemical treatments, plasma nitriding does not chip off. Minor wear marks are only visible through the wear of the BAR coating. The nitriding layer as surface hardening remains permanently intact.

Unique to Siegmund is the subsequent BAR coating of the welding tables and many tool parts, which takes place after plasma nitriding. The BAR coating (Black-Anti-Rust Coating) additionally planes the surface and increases protection against rust.

Find out more about the outstanding features of the Siegmund welding tables. Here you will find an overview of all the information and benefits.

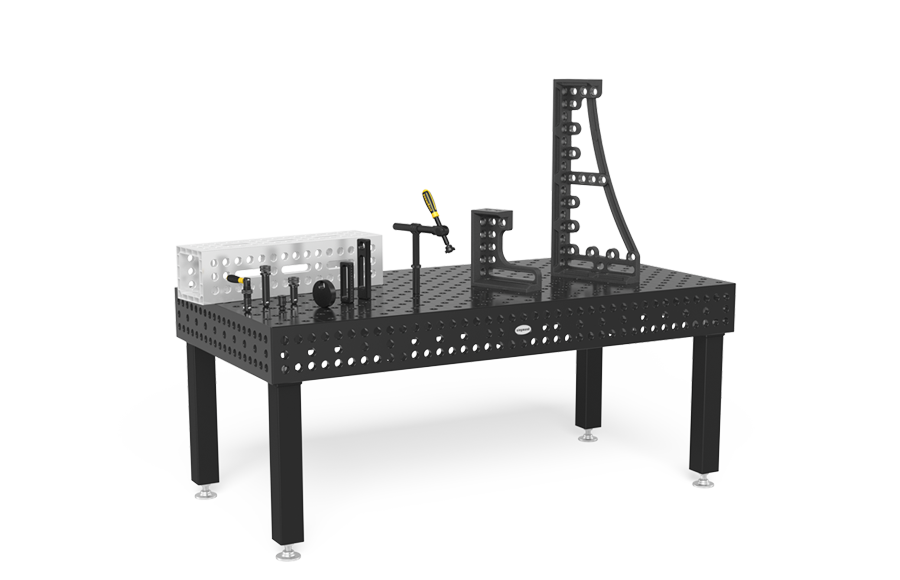

The Siegmund welding tables are available in three different systems – System 16, System 22 and System 28. Each system is characterized by different borehole diameters and load capacities.

Discover a variety of table variants made from different high-quality materials. Each variant is available in various sizes and can be combined with different table legs.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.