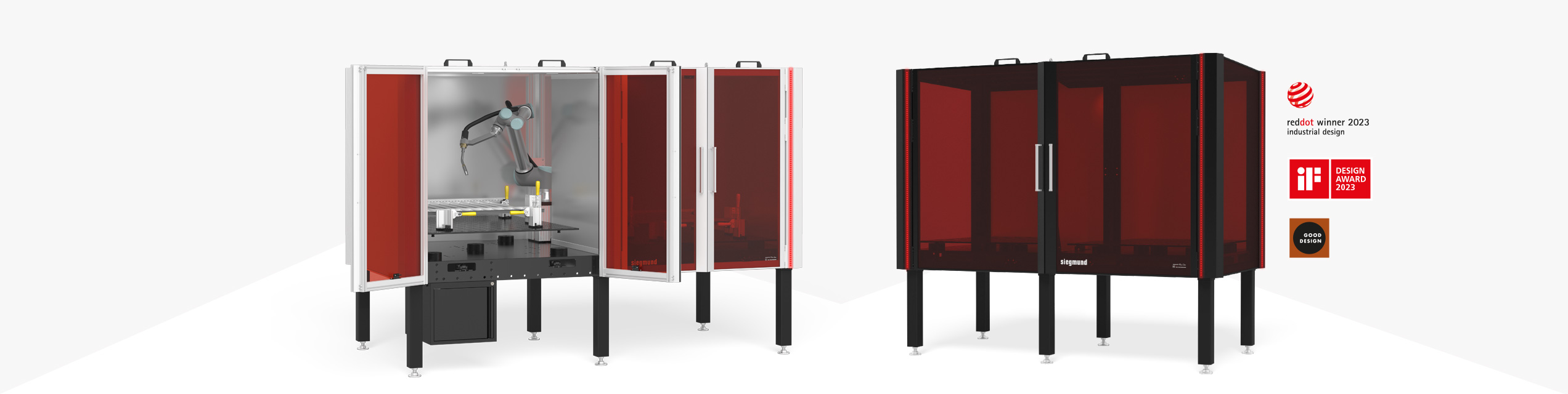

Robotics will witness the next revolution in welding technology. Traditional manually welded assemblies will in future be automated. As a world leader in the manufacture of welding tables, Siegmund now offer a new welding cell combining a new innovative design in clamping technology.

Configure a welding cell to match your Siegmund welding table. All doors and walls can be positioned as desired.

* Configurable: The marked components of the Siegmund welding cell can be individually adjusted. Please contact us personally. (Special equipment: Delivery time approx. 6 weeks)

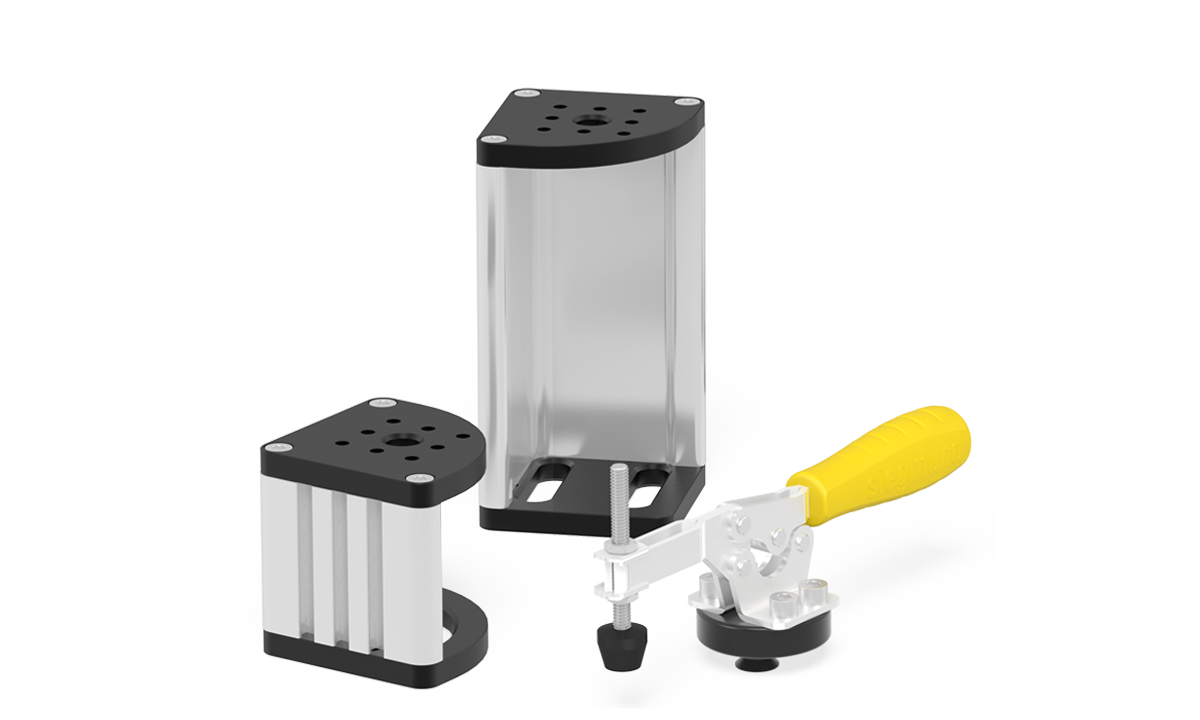

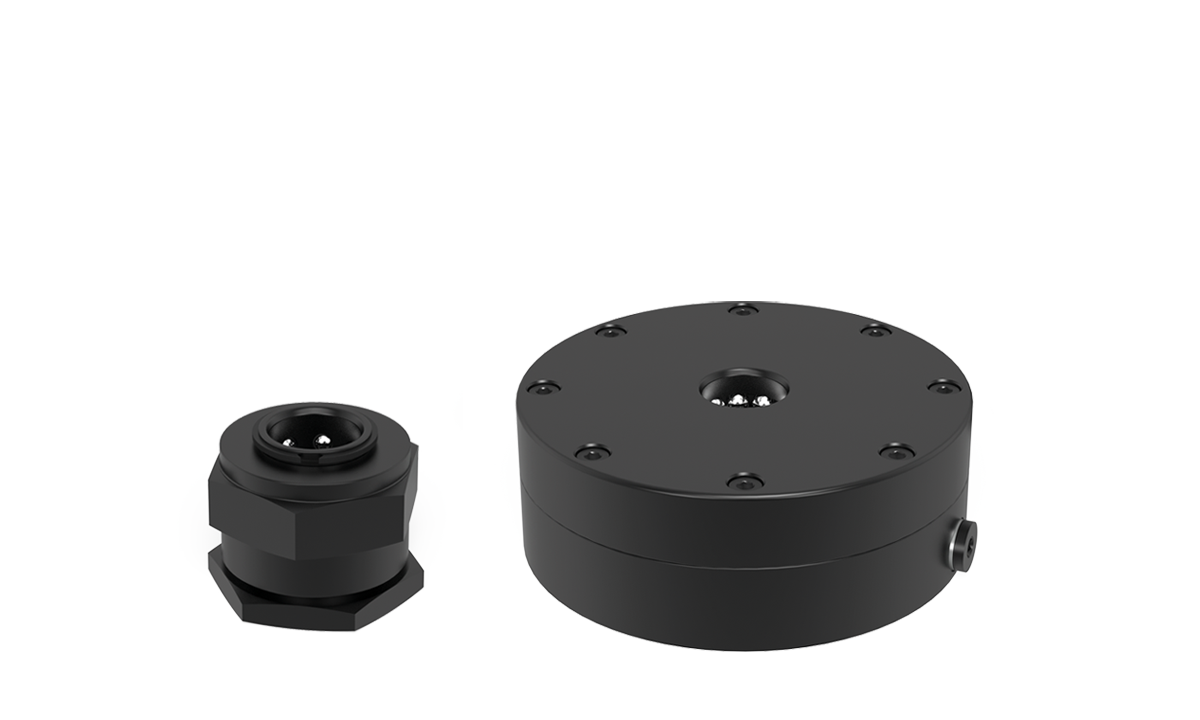

Benefit from a combination of Siegmund expertise in, a welding cell with zero point clamping, perforated plates and a new clamping system

For the simple creation of series fixtures with templates.

Simplified resetting for new fixtures and perforated plates.

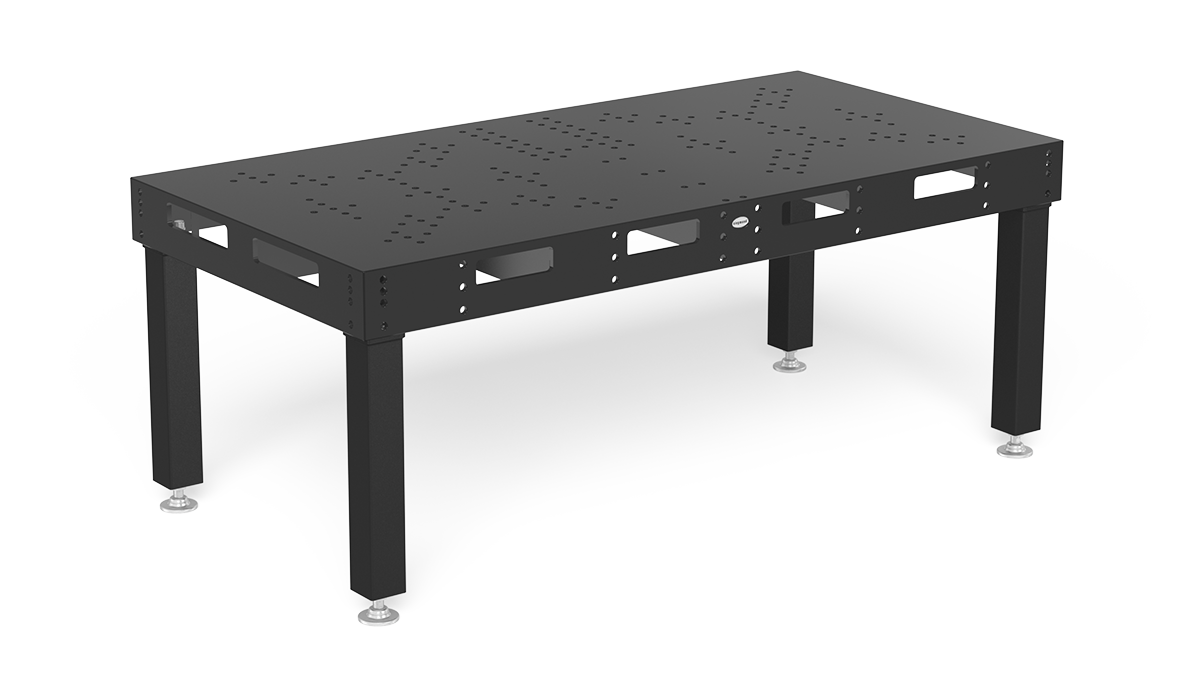

We recommend Siegmund perforated plates, welding tables or slot tables as a basis.

Some of the perforated plates have recesses for the console of the robot and are therefore optimized for the use in the Siegmund welding cell. In combination with the zero point clamping system and the new clamping system, set-up times in automation and series production are reduced.

Compatibility with standard Siegmund welding tables:

The welding cell is also available with standard Siegmund welding tables (2000x1000 mm, 2400x1200 mm, 3000x1500 mm) for a surcharge. With standard Siegmund welding tables we recommend to close parts of the bore holes with cover caps (Item No. 160238.10 and 280238.10) to avoid unwanted air circulations during welding. For more information, please contact our sales department at any time.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.