To be always one step ahead your competitors in terms of flexibility and accuracy and to fulfil the increasing demands, we offer you various options to expand your field of work individually and flexibly and to adapt to your specific needs.

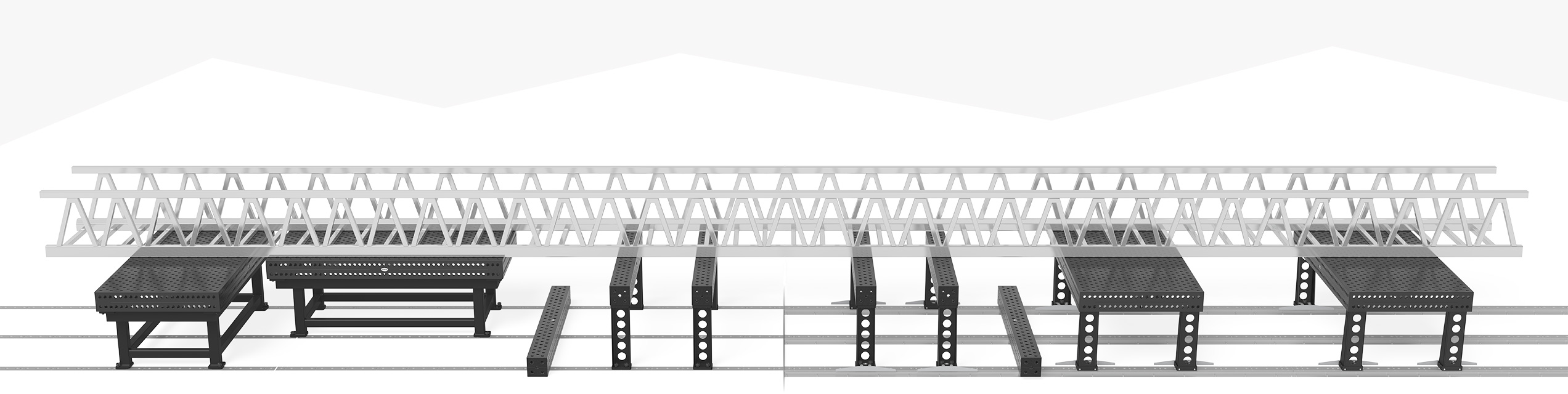

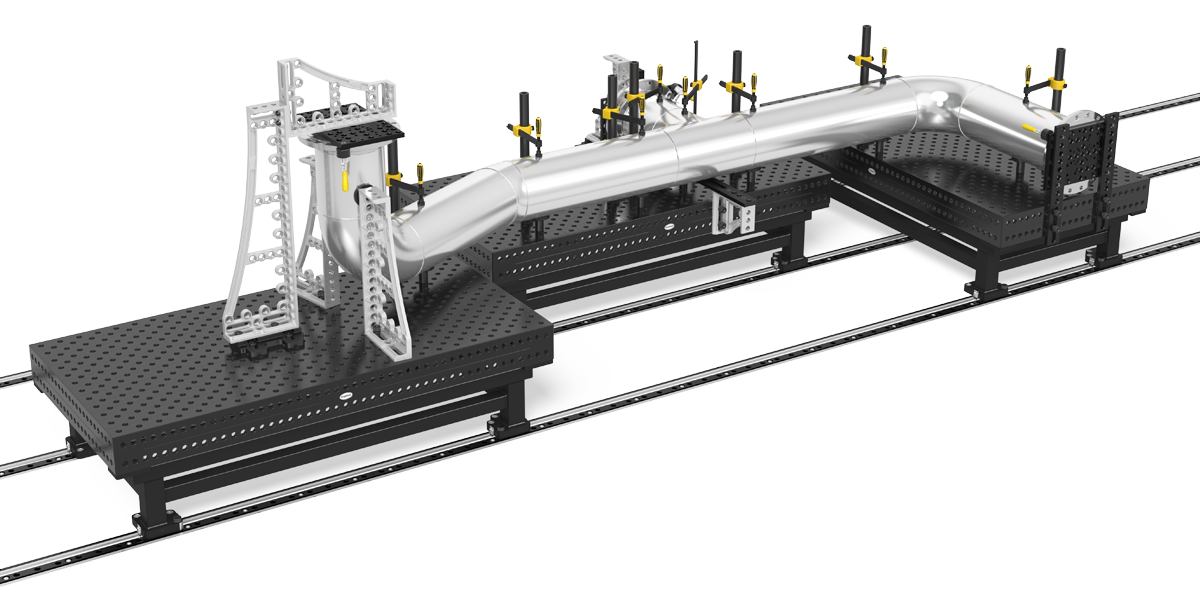

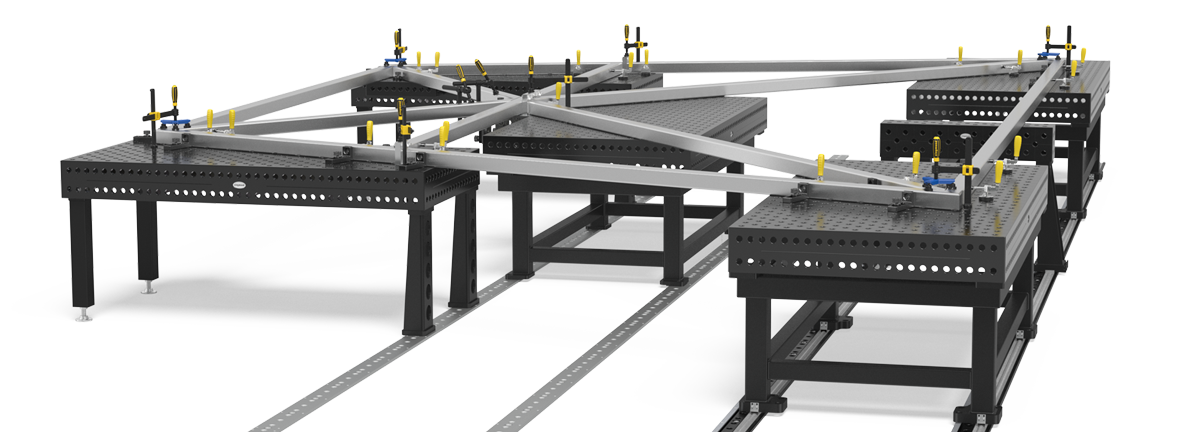

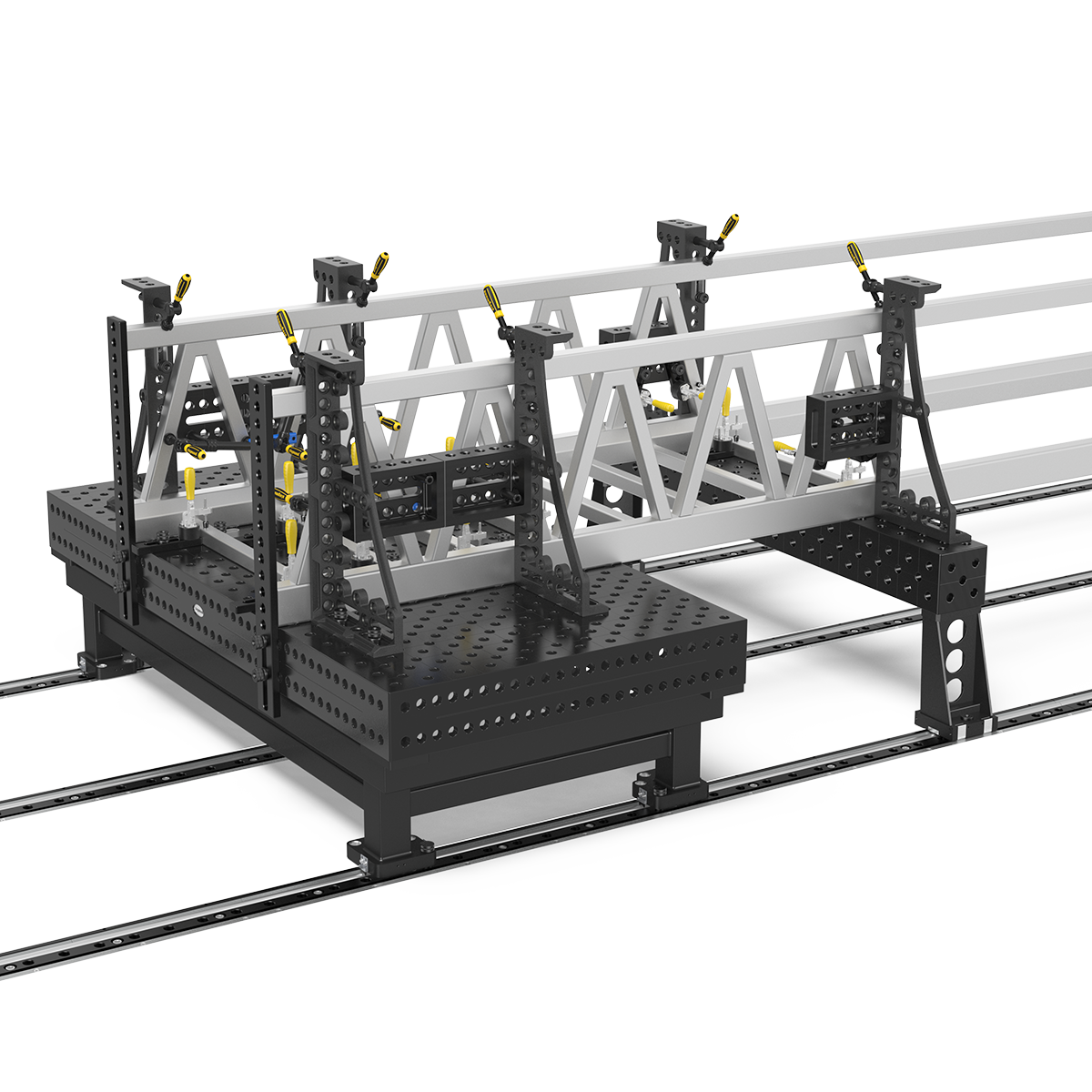

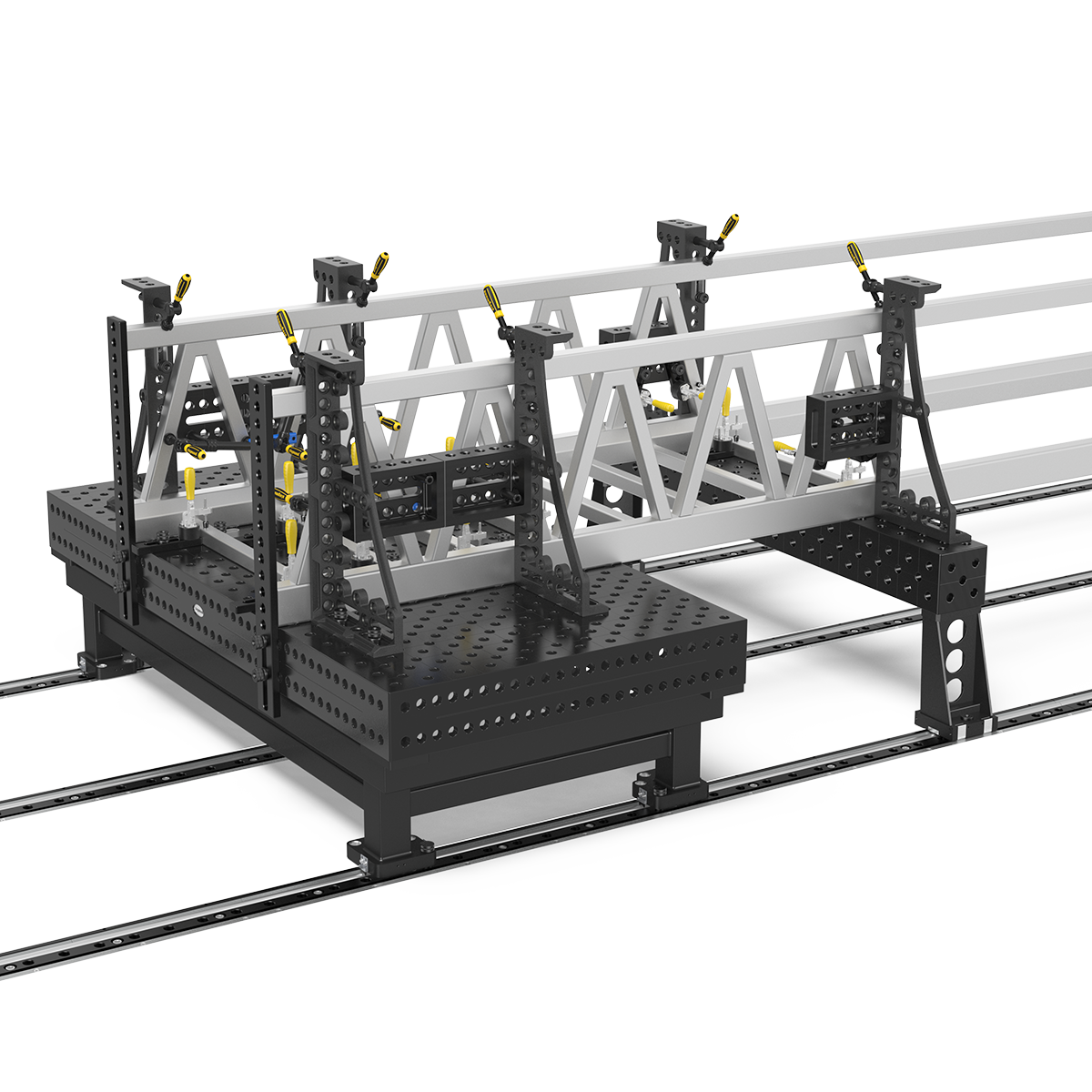

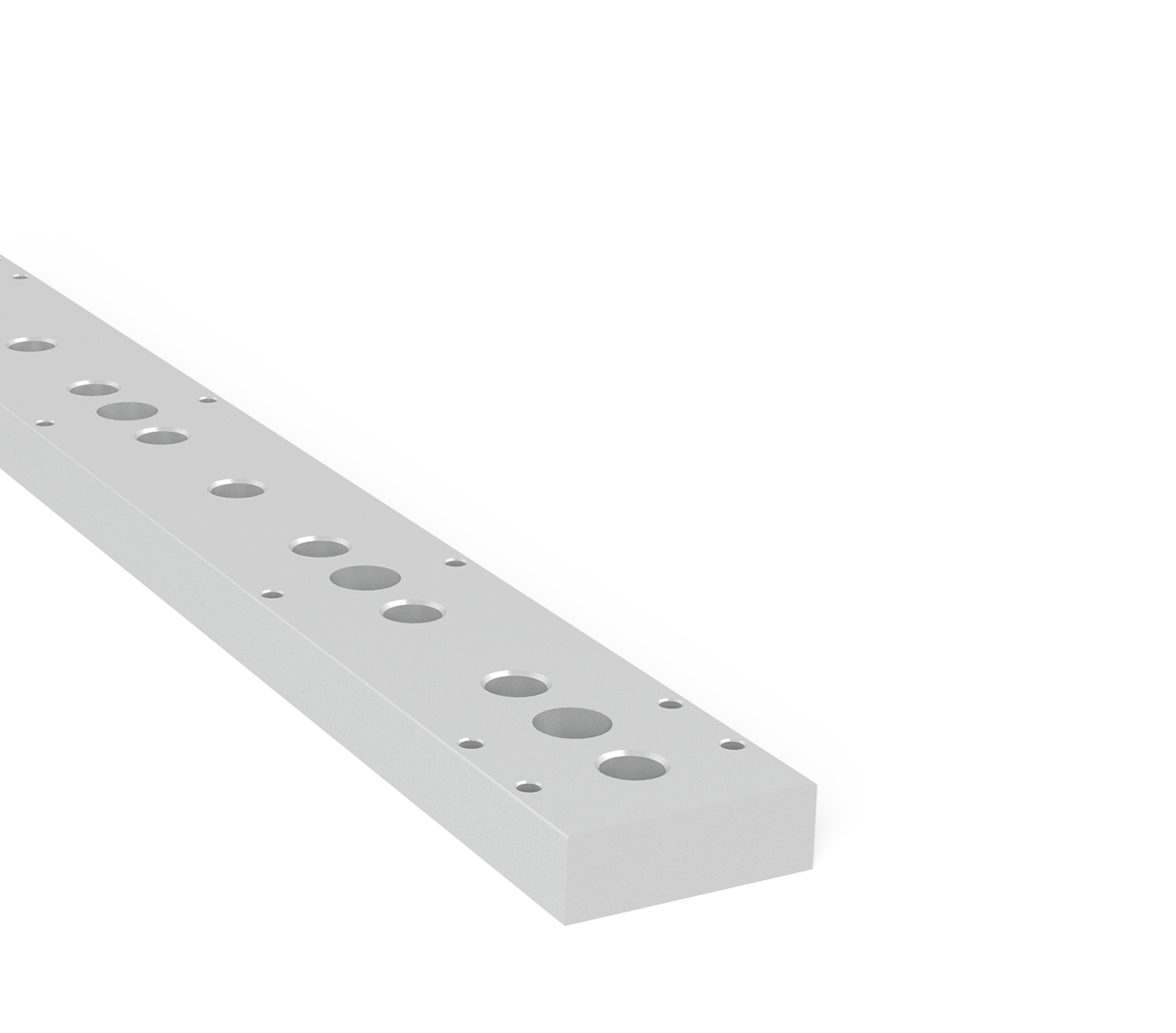

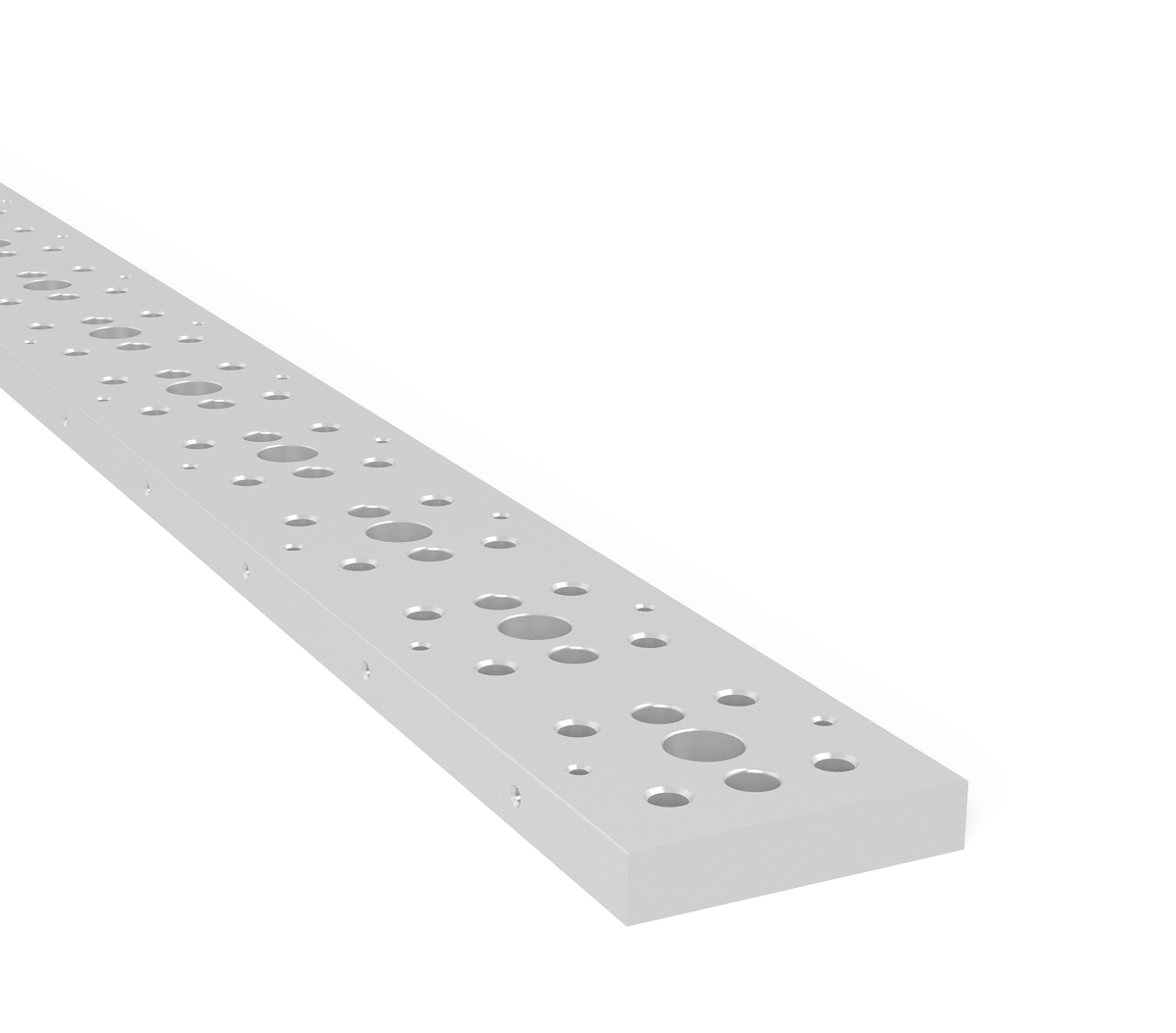

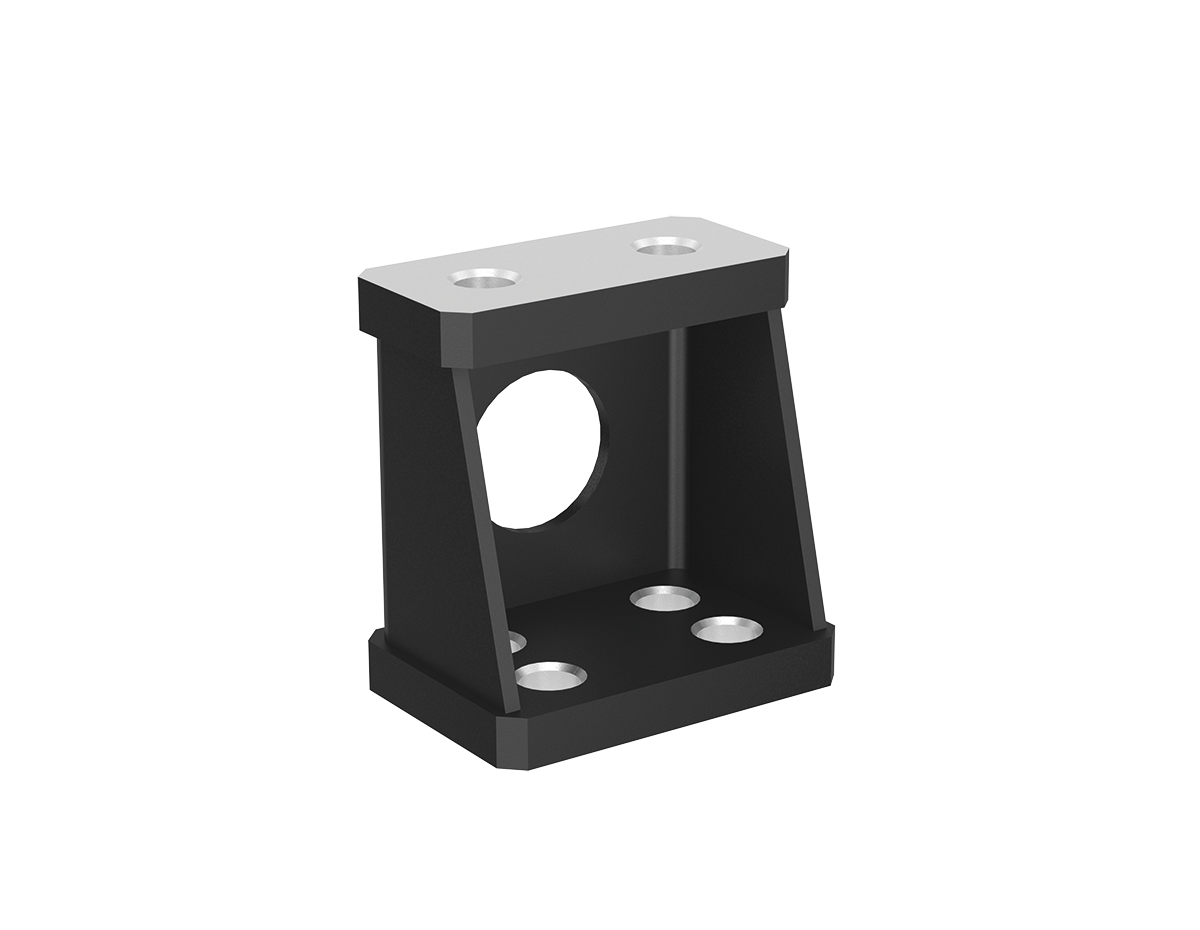

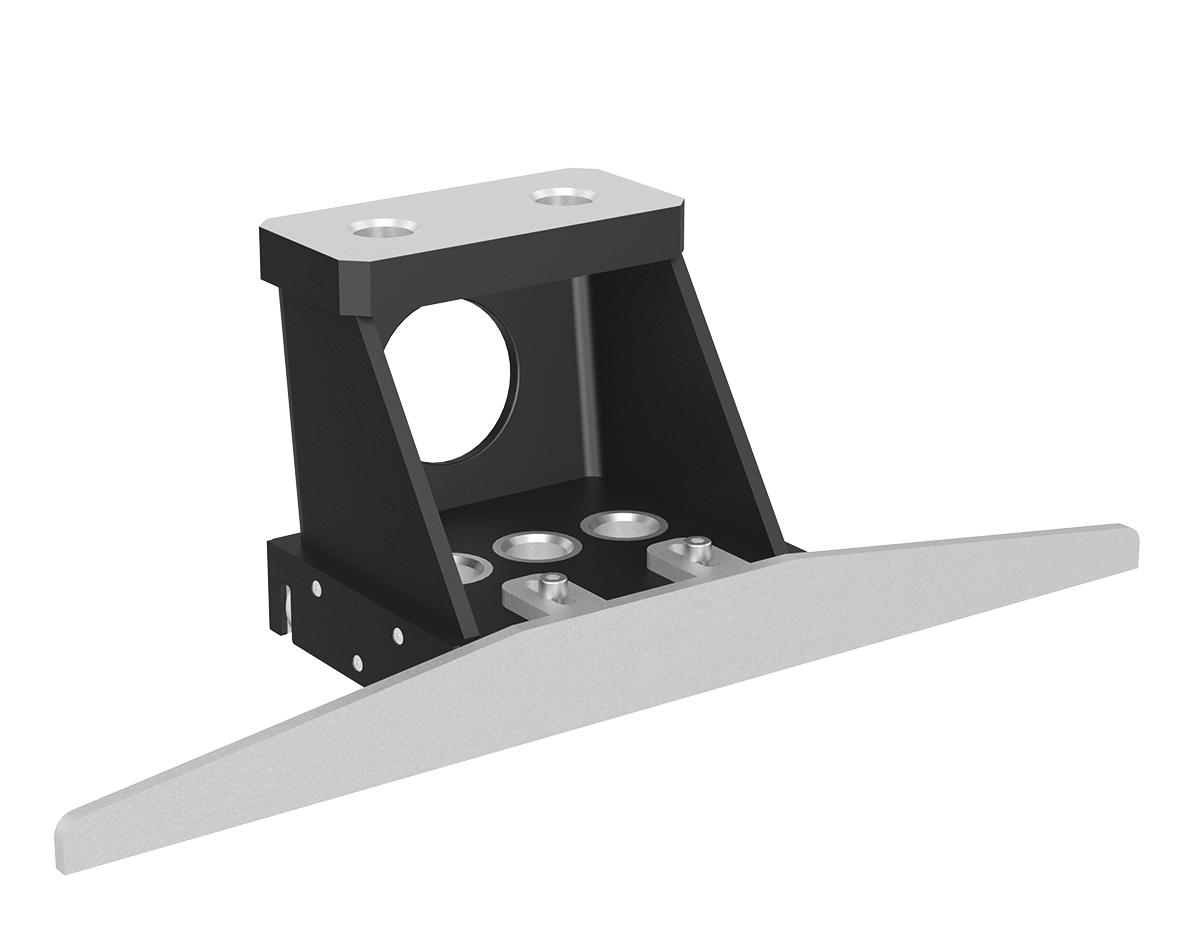

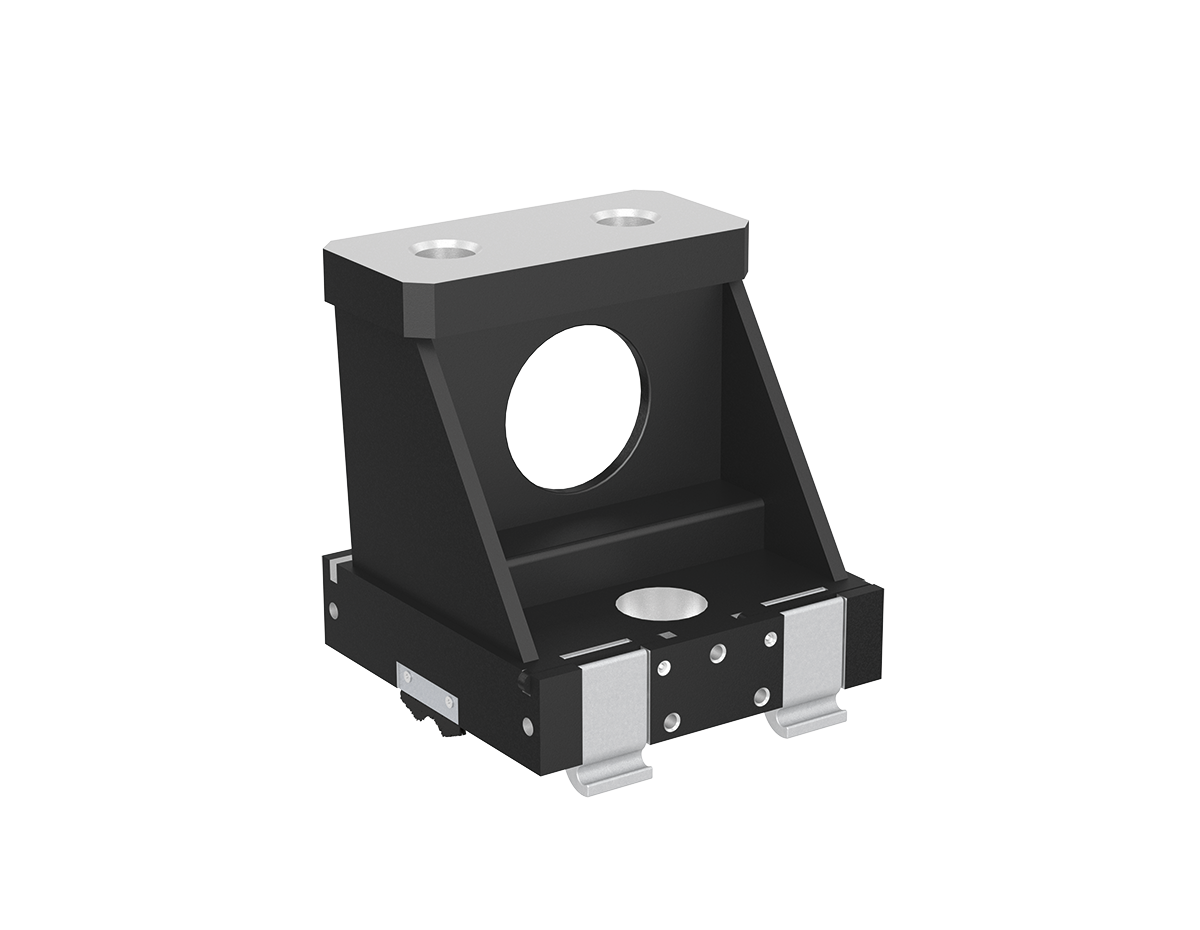

Thanks to the variety of the rail system, large products can be positioned, aligned and clamped very quickly. The combination of tables, connection frames and accessories (for example U-Squares) offers a multitude of fixtures. Through connection frames with integrated rolls and the fitting rail, tables and accessories can be moved easily and can be fixed in a 100 mm grid.

¹ Protection by crane or other lifting equipment required when moving.

² Tilt protection designed by moving without extra load. Maximum design height 850 mm.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.