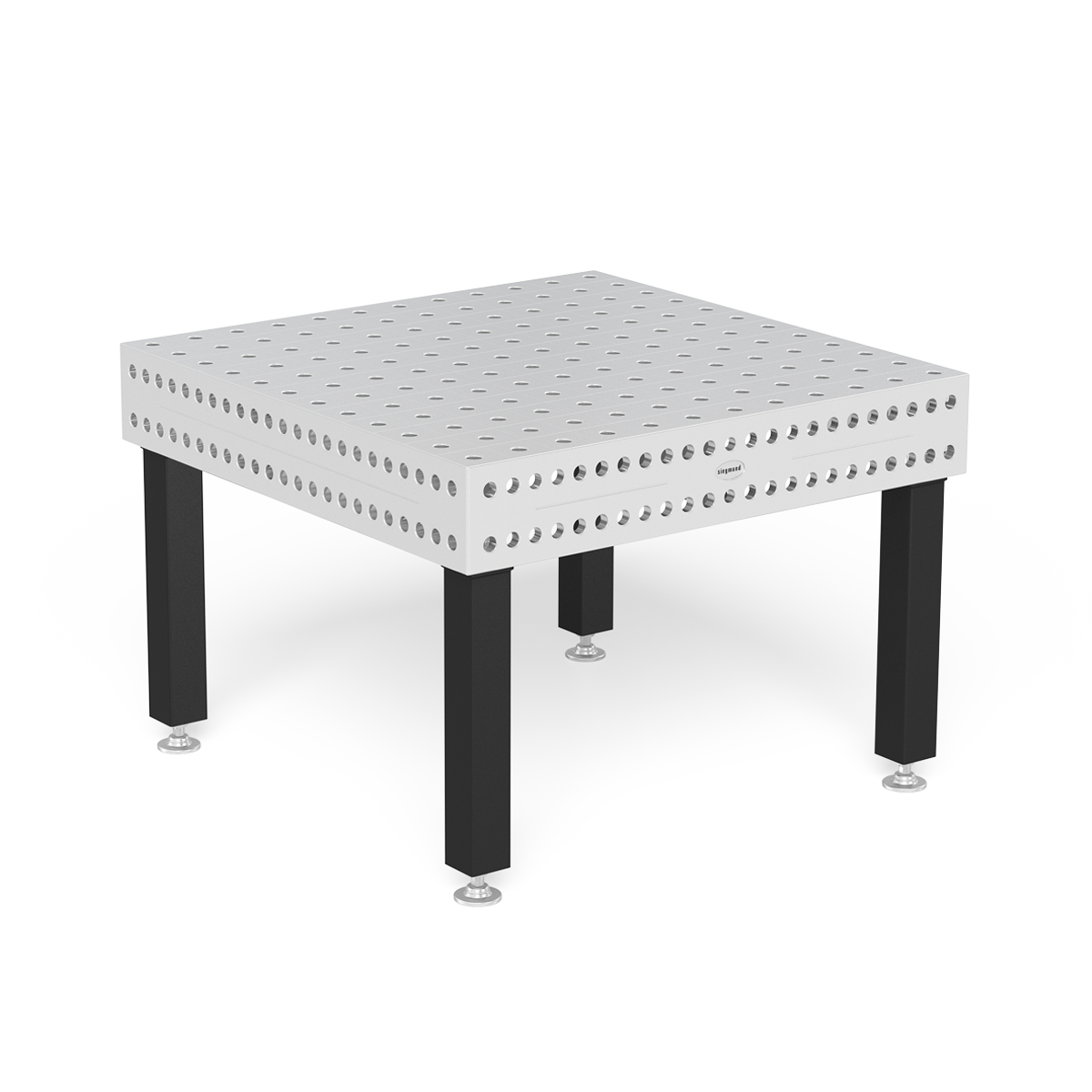

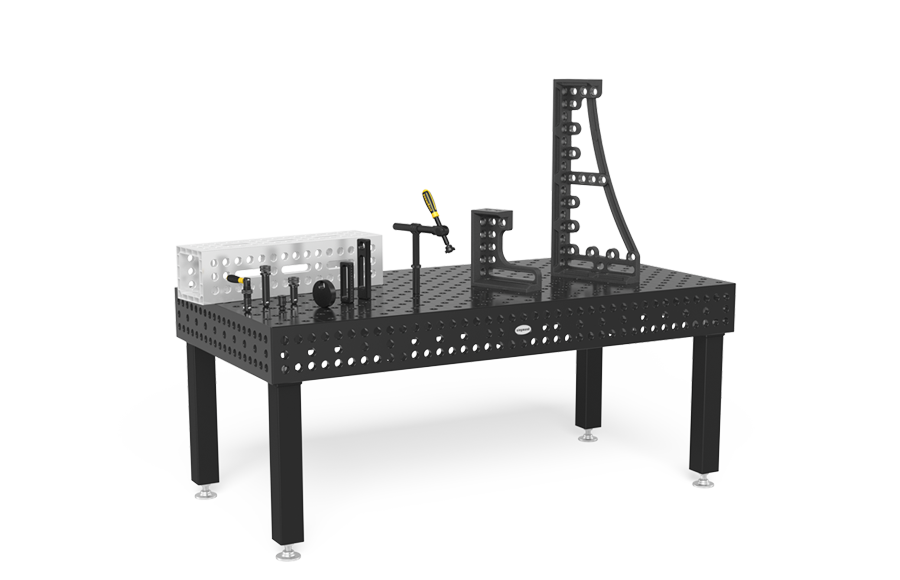

Discover a variety of table variants made from different high-quality materials. Each variant is available in various sizes and can be combined with different table legs.

Find out more about the outstanding features of the Siegmund welding tables. Here you will find an overview of all the information and benefits.

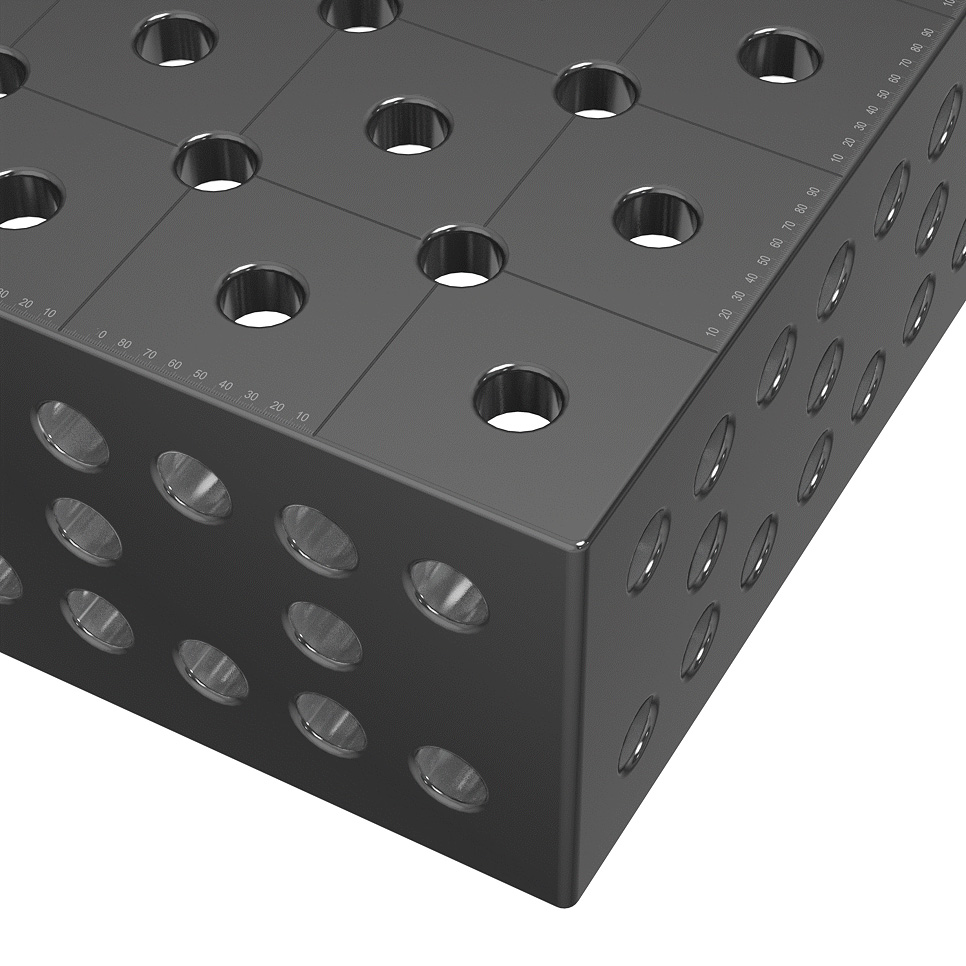

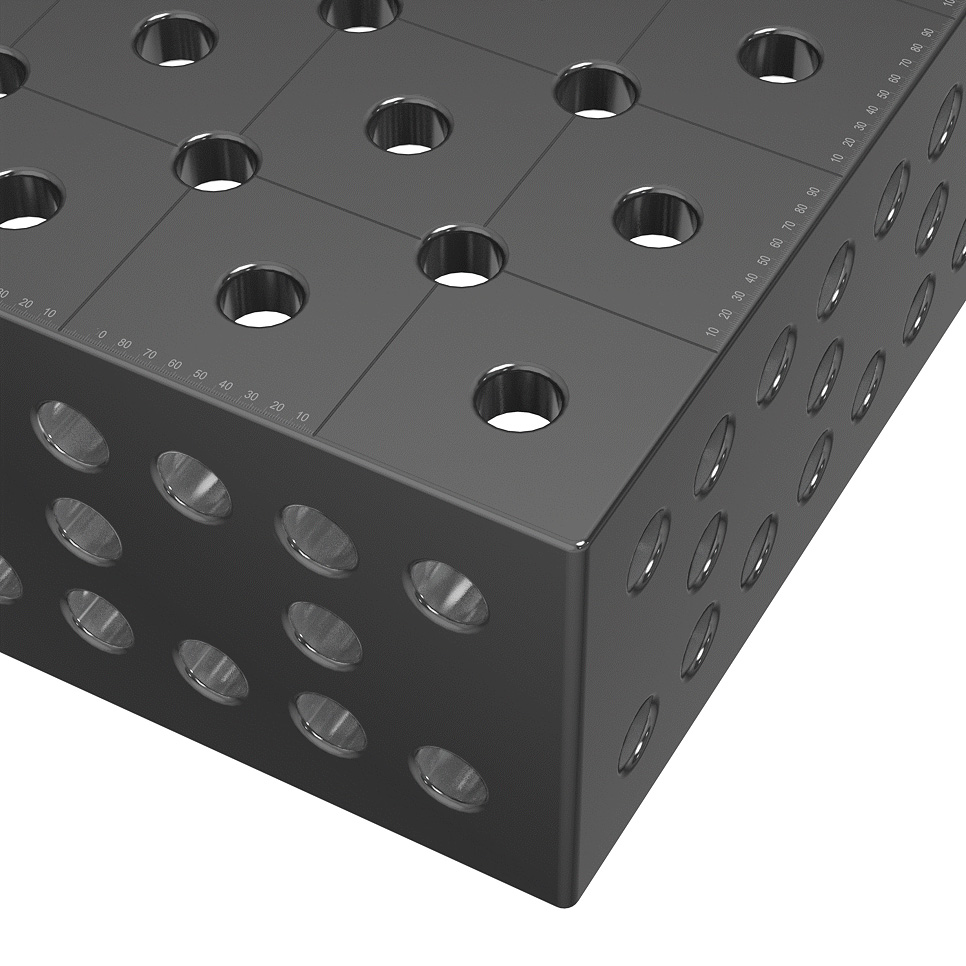

The Siegmund welding tables are available in three different systems – System 16, System 22 and System 28. Each system is characterized by different borehole diameters and load capacities.

The unique materials and finishes are characteristic of the Siegmund welding tables. Here you will find all the information about the available options.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.