If our standard offer does not include the right table size for you, you will find your desired size in our special size calculator. Select your system and material and specify the size of the table.

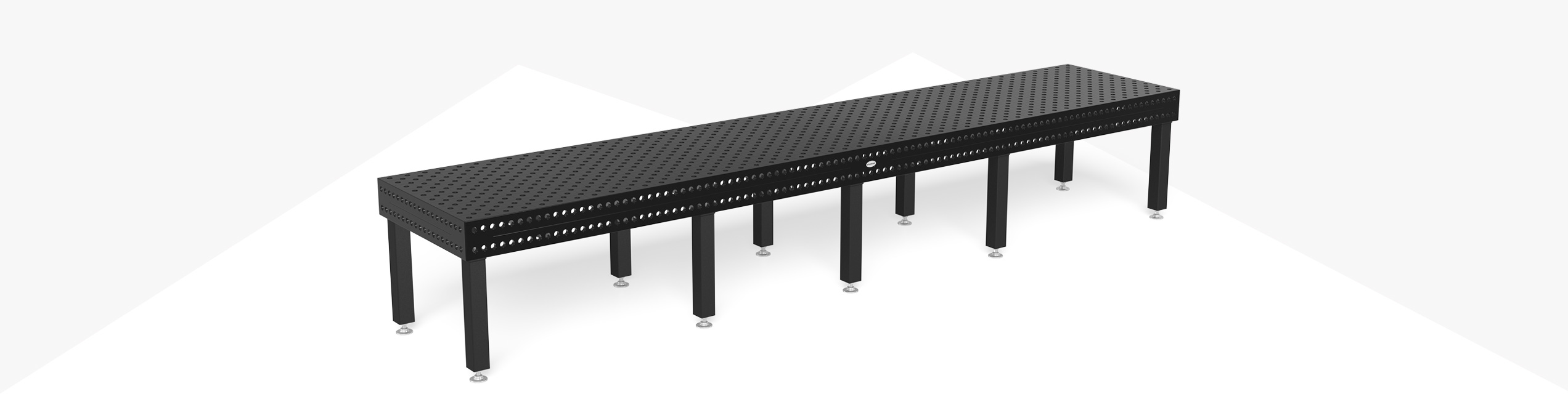

| Length: | ${article.length} mm |

| Width: | ${article.width} mm |

| Height: | ${article.height} mm |

Discount for special sizes: starting at 2 pieces: 5%, starting at 5 pieces: 10% (Not valid for standard sizes)

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.