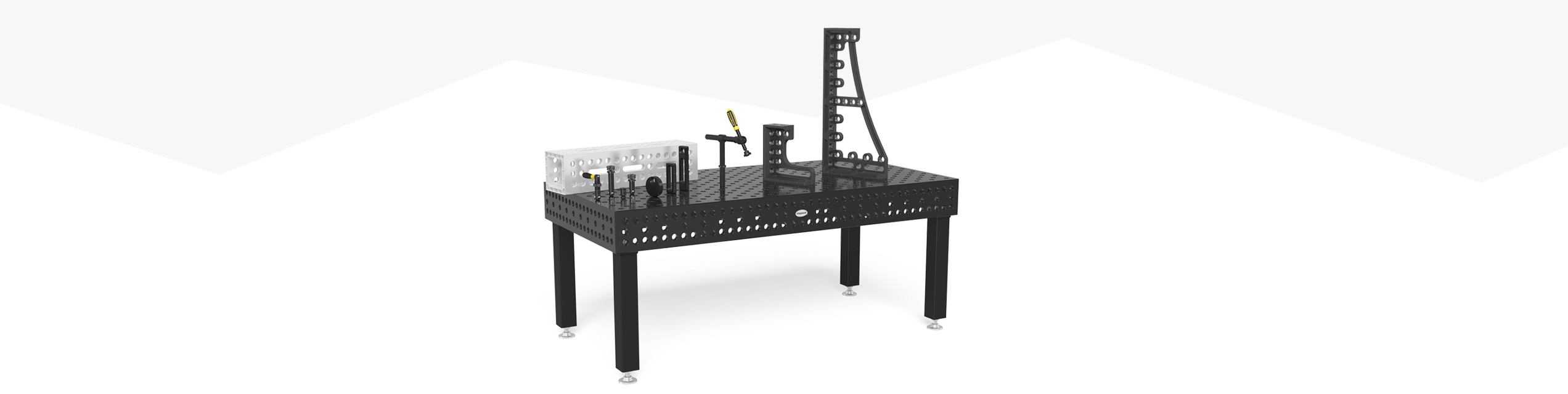

Our welding and clamping tables are characterized by the highest quality, resilience and precision. Not only welding work can be carried out on our tables, but also clamping and assembly work of all kinds with materials such as wood and plastic. We have invested a lot of development work in our welding tables in order to offer you a highly efficient working basis today.

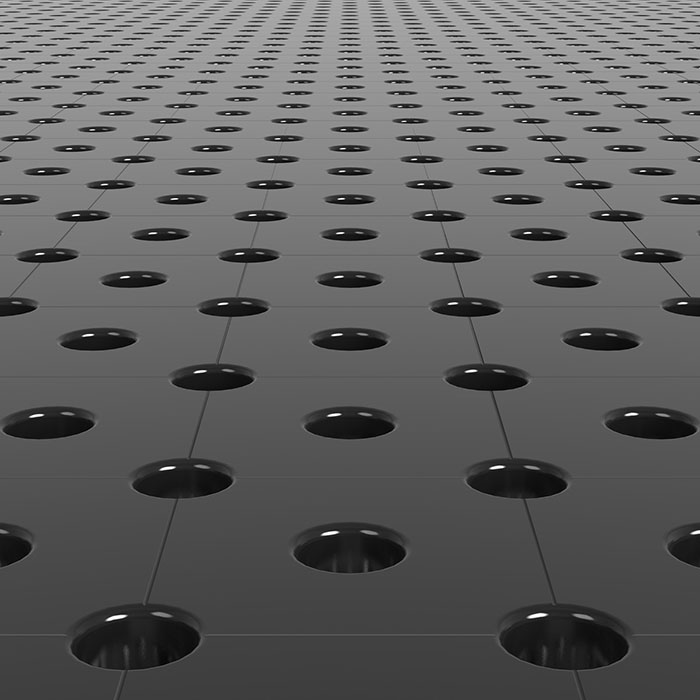

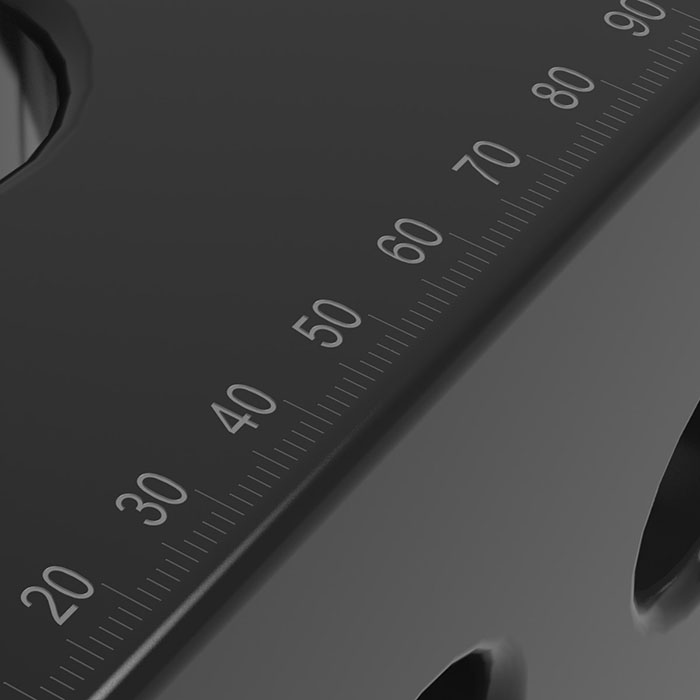

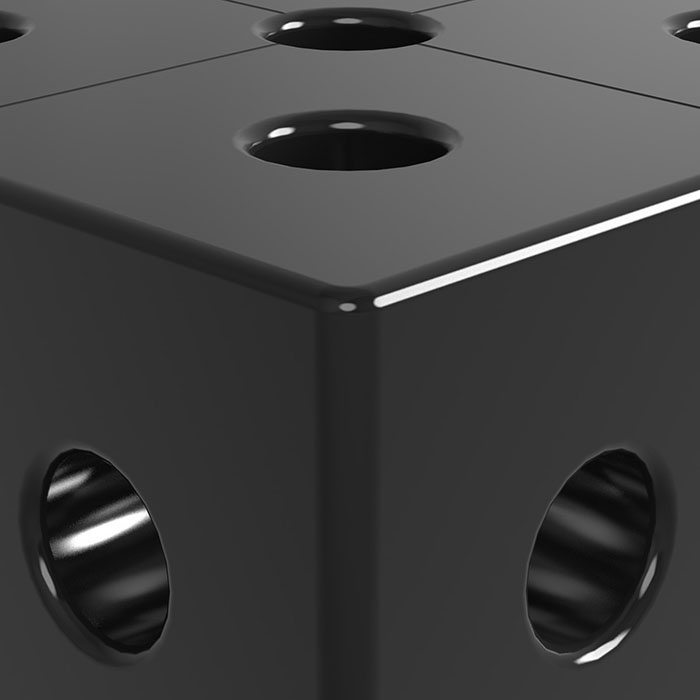

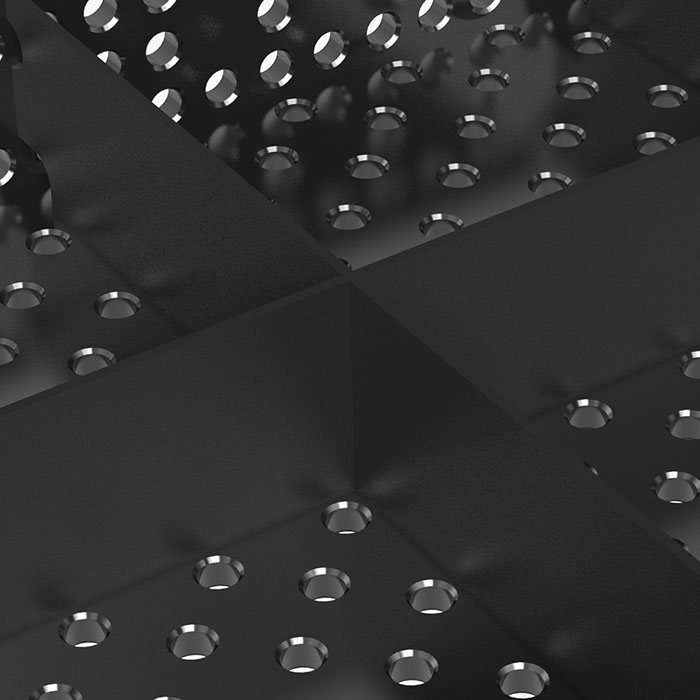

Thanks to the boreholes in our welding tables, an extremely flexible and versatile clamping surface is created. This gives you the opportunity to quickly and easily produce a wide variety of constructions using squares, stops and clamps. The excellent precision of our welding tables enables you to position the components exactly and thereby achieve very good repeatability. We offer a perfectly coordinated modular system for every application, with which you can work conveniently and efficiently.

The through-hardened tool steels X8.7 and X8.8 are available exclusively from Siegmund. They stand out due to their exceptional base hardness, ensuring high resistance to impact forces.

Plasma nitriding and subsequent BAR coating increase the surface hardness and provides effective protection against scratches, corrosion, and the adhesion of weld spatter.

The unique combination of high base hardness and surface finishing results in an exceptionally durable and wear-resistant surface that performs even under the most demanding conditions.

An impressive load capacity of up to 2000 kg per table leg (depending on the table leg and system) is made possible by the robust and solidly constructed table legs.

The high stability of the tabletop is ensured by a material thickness of up to 25 mm (depending on the system) and reinforcing ribbing.

Rounded boreholes and edges make it easier to insert bolts and accessories and protect both the table and the workpiece from damage.

The Siegmund welding tables are available in three different systems – System 16, System 22 and System 28. Each system is characterized by different borehole diameters and load capacities.

Discover a variety of table variants made from different high-quality materials. Each variant is available in various sizes and can be combined with different table legs.

The unique materials and finishes are characteristic of the Siegmund welding tables. Here you will find all the information about the available options.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.