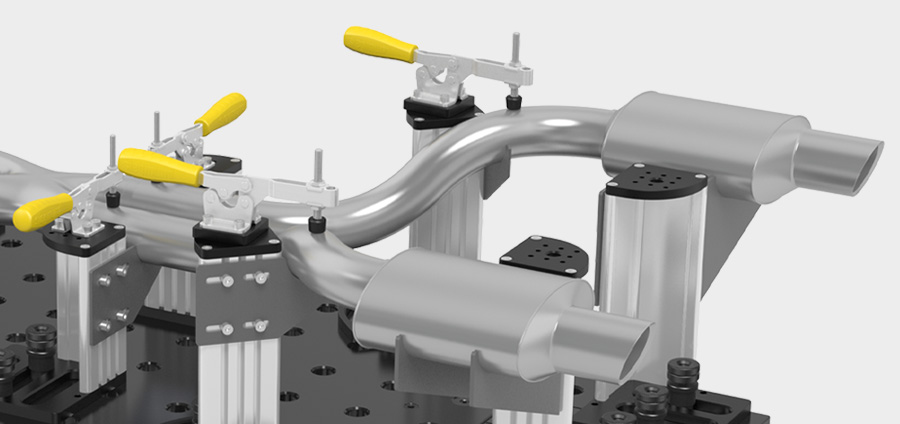

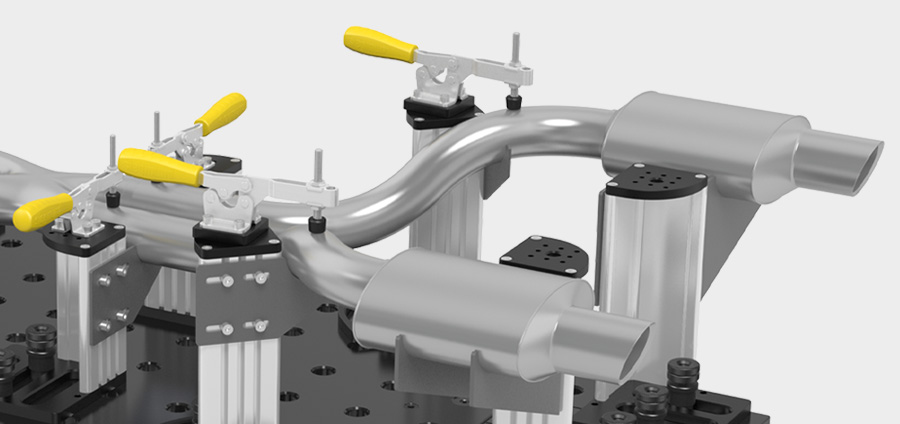

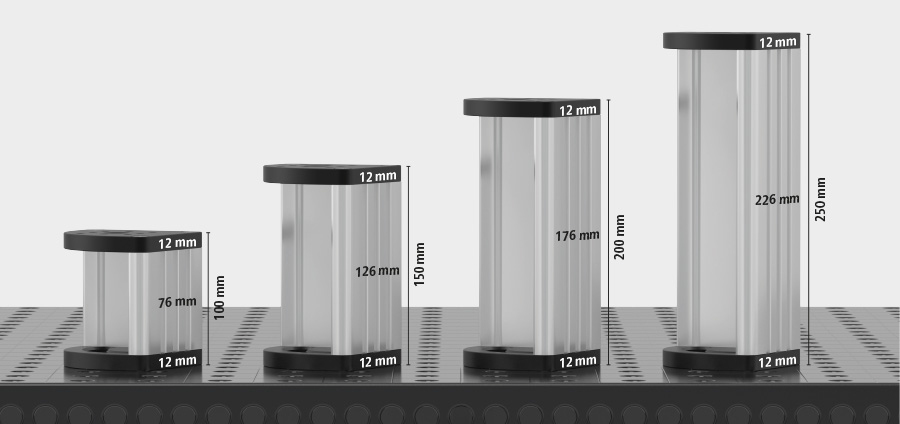

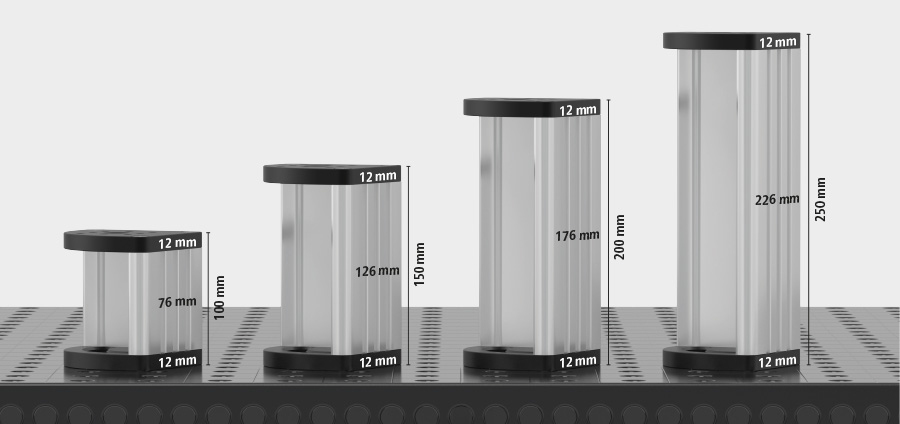

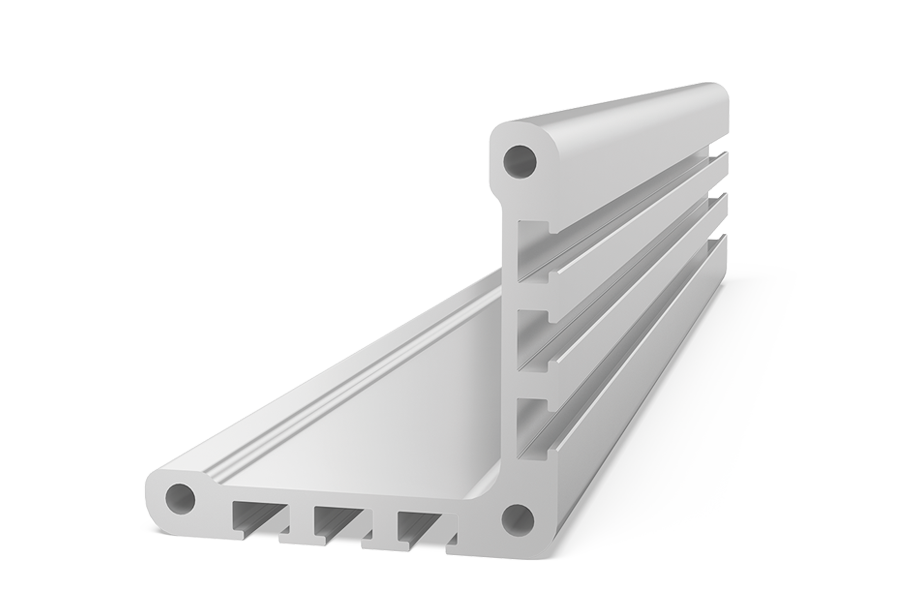

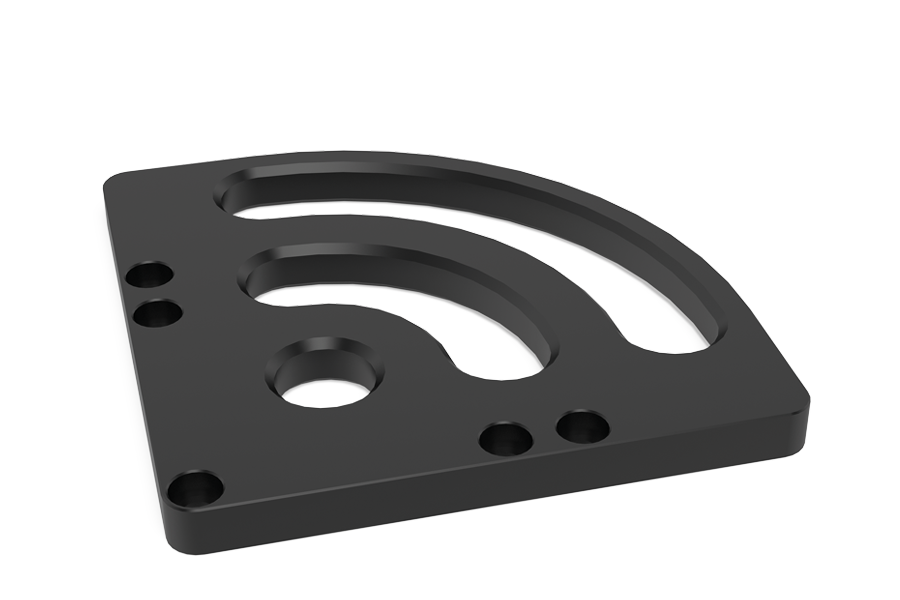

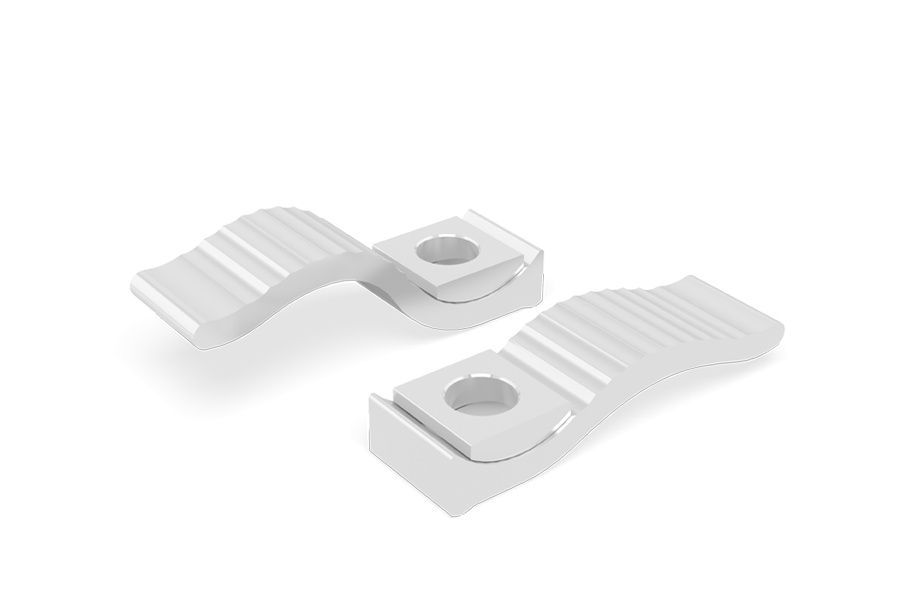

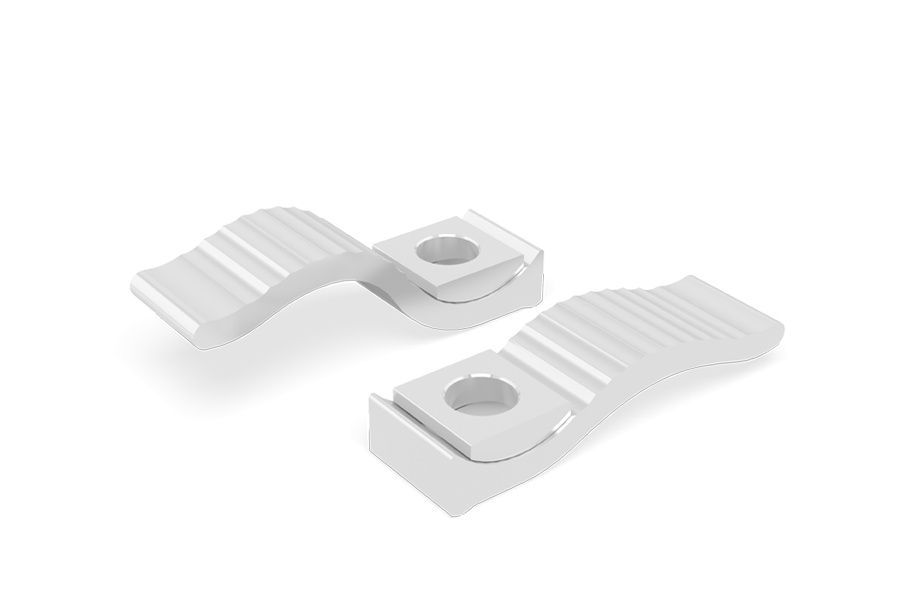

Compose your individual devices from aluminum profiles and various cover and base plates according to your requirements and produce small to large series quickly, easily and inexpensively. You can work with your custom-made templates – whether laser parts or from the 3D Printer. The templates can be attached in the T-slot of the aluminum profiles with square nuts and screws. The templates are aligned via the table surface – as a basis we recommend Siegmund perforated plates, welding tables or slot tables. The height of the component is determined by the length of the aluminum profiles and can be individually adapted by cutting to size. The aluminum profiles are available in fixed lengths or as mass product.

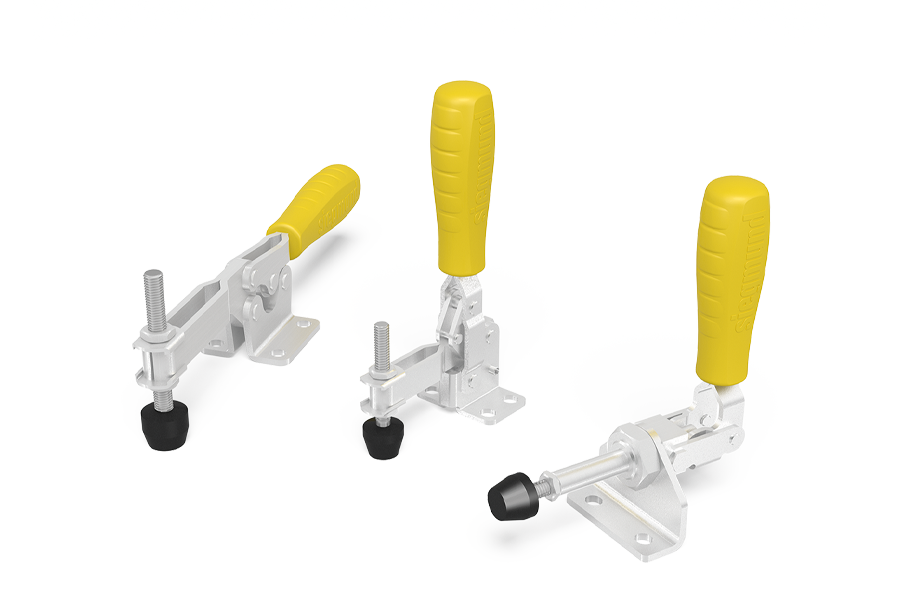

The Siegmund clamping system is available in all systems and, as usual, can be combined with all the accessories in our product range.

Individual fixtures can be assembled from aluminum profiles together with various cover and base plates. Small to large fixtures can be easily and quickly built at minimum cost.

Supplementary or accompanying content from "YouTube" is provided in this area. You can show and hide this content with one click.

I agree that I want to show external content. This can lead to personal data being passed on to third party platforms.

More information about Cookies and social-media-plugins can be found in our Data Protection Declaration.